High speed and precision of patterns digitization!

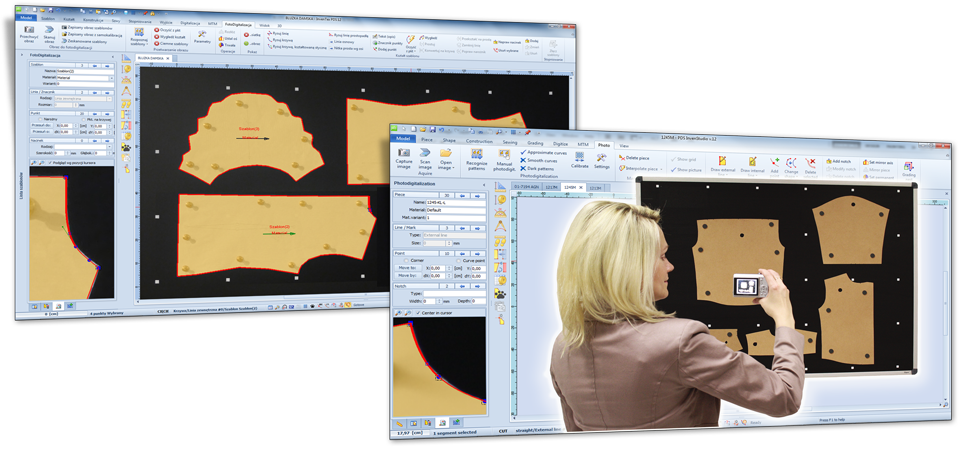

In order to noticeably speed-up digitizing process in garment textiles and furniture production sector an extremely technologically advanced InvenTex Photo Digitizer (abbreviated to InvenTex IPD) module was implemented. By means of a digital camera or flatbed scanner we can very easily process arbitrary-sized carton made patterns into its digital equivalents. After taking the picture the system is automatically calibrating the patterns to remove errors coming from perspective and optical issues. Next in a very short time the shapes of all patterns are automatically recognized and saved on computer’s hard disk. Image processing algorithm provides high precision and efficiency of shapes recognition. As a novelty it supports a camera installed on a fixed arm attached to the table or a camera which is installed on a tripod or held in hands of the operator. The former option gives full mobility without the need to perform separate calibration of the system after each change of camera’s position in reference to the surface where we placed our patterns. Is assures the highest precision and possibility to process photos from the archived library any time.

Advantages for the user:

- highest precision of pattern shape recognition

- highest precision of pattern shape recognition

- digitizing of multiple patterns at the same time

- mobility of the photo-digitizing – photos can be taken outside of the company, eg at the customer’s site

- lots of photos can be taken at once and processed at the later time

- efficient digital archiving of big quantity of patterns

It takes only three simple steps to speed-up patterns entering to the system 10-times and increase efficiency!!

Take a photo or

scan of the patterns

Recognize shape

of patterns

Save or export

the model

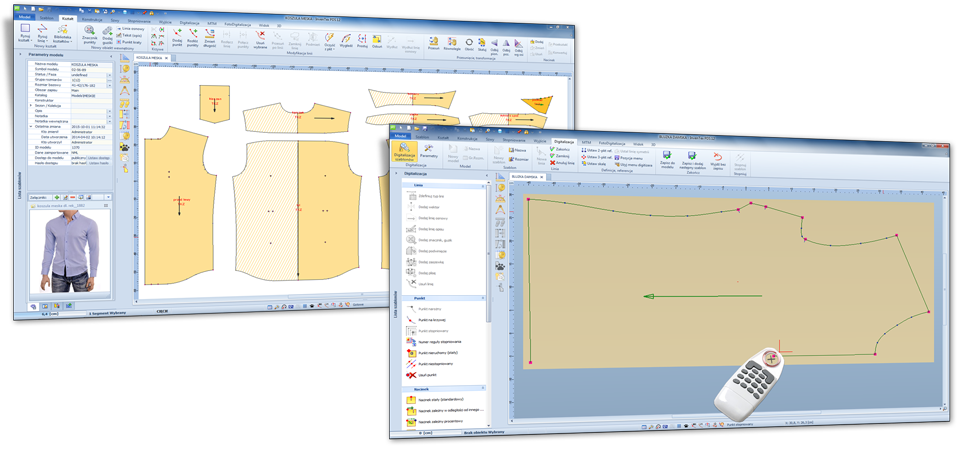

One software – three digitizing methods:

You’ll always choose a method which is most suitable for your needs. IPD is built-in into the InvenTex PDS assuring perfect cooperation between these modules. InvenTex IPD can be also delivered as an independent system which can be used with any CAD system.

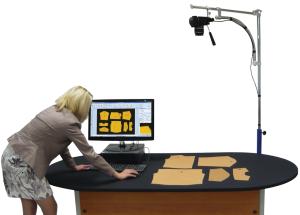

Professional method –

camera attached

to a tripod

- high efficiency thanks to a direct connection between the camera and computer which is processing photos

- high efficiency thanks to a direct connection between the camera and computer which is processing photos

- continuous preview of patterns on the computer screen assures correct cropping of the image

- any type of table covered with black cloth can be used

- solid tripod eliminates frequent re-calibrations

- stiff patterns don’t have to be fixed to the table

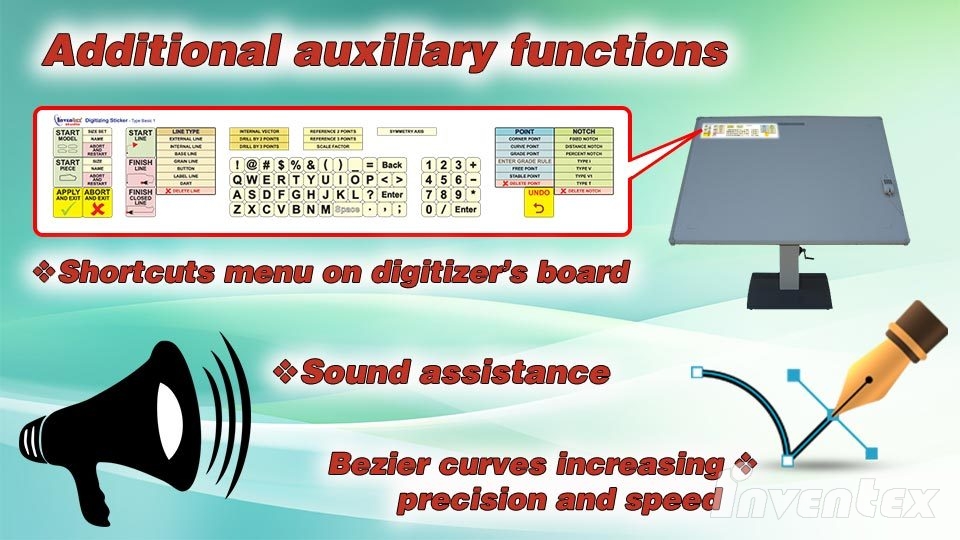

Innovative method –

auto calibration

of the system

- any type of digital camera with min. 6 MPix sensor can be used

- full mobility of taking photos, then images can be transferred from flash memory card and photo-digitized

- full mobility of taking photos, then images can be transferred from flash memory card and photo-digitized

- auto calibration provides precision of picture processing even after a few years since the photo was taken

- saves space if photo-digitizing table is fixed on a wall

- selected models of digital camers can be permanently connected and controlled directly from the program

- best price/usage advantages ratio

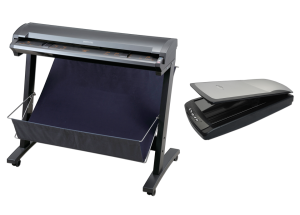

Method with flatbed

scanner and auto

calibration

- even the cheapest A4 flatbed scanner can be used

- very comfortable digitizing of small patterns (eg lingerie)

- only half of the pattern can be scanned if it’s symmetrical

- handy and very fast in usage

- optical correction of taken picture of the pattern;s shape is not necessary

- can be used in parallel with other method during photo-digitizing of patterns from the same model

- a professional wide format scanner can be used

Photo-digitizing it’s a production-proven patterns digitizing method.

Classic digitizer today means an outdated technology.

Get rid of your “paper-made collection” in just a few days.

Do not hesitate! …it’s time for new, better technologies!!!