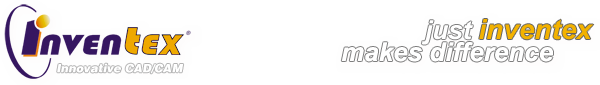

Machine is capable to spread all types of textile materials. Spreading machine is equipped in conveyorized cradle, drive system „direct-drive”, operators platform and easy in use operators touch screen panel and all wheel drive system. Automatic edge control system and tensionless spreading as a standard feature. also available automatic cutoff system of every layer. Special attachment for spreading in a zig-zac mode with end of material press bars as a standard feature. On demand, the machine may be delivered with special equipment enabling to spread folded material (from pallet) or tubular knitwear material.

Important technical features:

- the cradle offers fast and easy loading and unloading of the material, in addition thanks to possibility to til it backwards – even frequent change of material at short markers is no problem

- electronically controlled conveyor belt of the cradle, precision of unwinding and rewinding of the material

- unwinding of material by the conveyor belt of the cradle related with electronically controlled tension of the material in real time, ensures proper spreading result

- cradle equipped in two wide conveyor belts prevent the material from being pulled under the belts, which very often is the case in spreading machines with multi-belts system

- online monitoring of the tension of spreading ensures tensionless output

- spreading of the material in a face-up mode with automatic cutoff of every layer of the material, and spreading in zig-zac mode without cutoff of every layer of material

- pallet for folded knitwear as a standard feature

- all four wheels drive

- possibility of adjusting of drive wheels in wide range enables to adjust them to set up the machine on a existing spreadin table of the customer, lowering cost of installation

- automatic detection of the edge of material with adjustable sensitivity of the sensors, enabling to set up the machine to all types of used materials

- integrated high speed cutoff device

- automatic adjustment of the height of the spreading head

- semi-automatic system of material lead into the machine

- solid operator’s platform, with photoelectric closeup sensors, ensures instant stop of the machine, when men or any other object appear in the vicinity of the sensors

- end of roll sensor will automatically stop the machine when the material has finished

- machine controlled with use of PLC module (less wires, effective control of the working parameters of the machine, low break down, fast and accurate auto diagnostics of possible errors and problems

- intuitive and clear touch screen panel for setup and parameter settings of for example: length and number of layers in a marker,parameters of the tension of spreaded fabric, speed of spreading, acceleration, and many other features which are important for proper work

- all available in multiple languages

- electronics made in a latest technology SMD

- programmable acceleration and retardation at extreme points of the spreading table

- sensor-encoder reads current position of the spreading machine on the table, possibility to work at any plece of the spreading table

- available counter of the linear meters of the spreaded material

- double function shifter, controlling move of the spreader along the table or tension of the fabric

- auto-test diagnostics engaged at every start of the machine or manually at demand of the oprator

- safety switch “Quick-Stop” at both sides of the machine – comply with the safety features of CE/UL