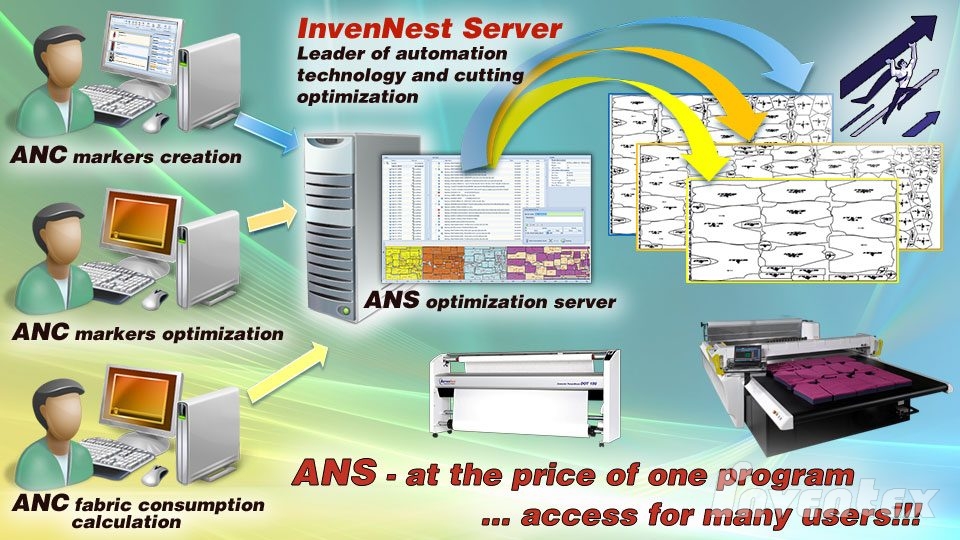

Big fabric savings and work time reduction!!!

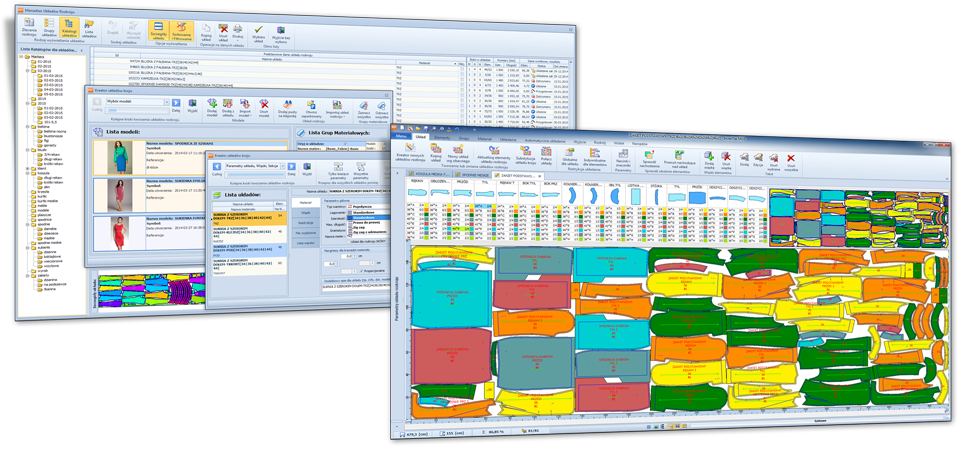

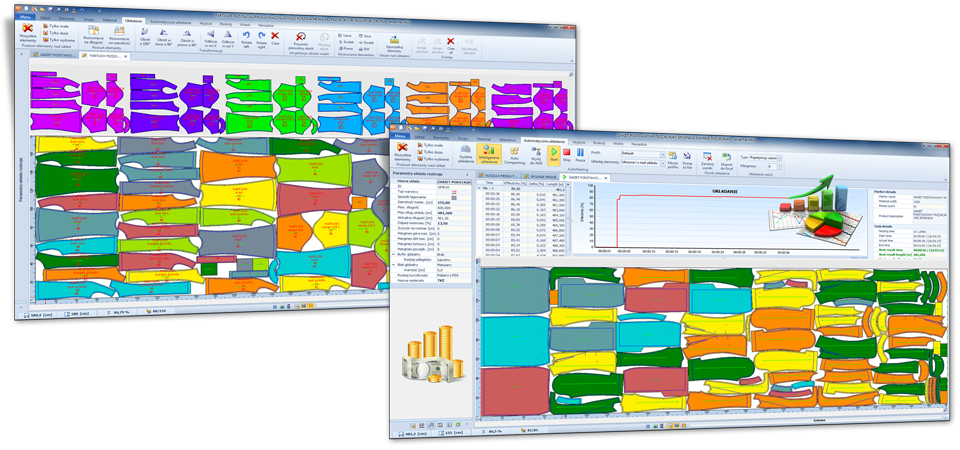

Interactive creation of cutting markers is a very strong feature of the InvenTex system. Intuitive grouping of icons and friendly to use functions assure easy usage even for the employees without expirience with computers. After only one single day of training the user is able to create optimal cutting markers. InvenTex MGS can be successfully used by a person who was working a cutting room before. There is no need to hire additional employee! Introduction of the InvenTex MGS module brings immediate, minimum 10% savings in fabric consumption in comparison to manually created markers. The efficiency of production preparation process is also increasing incomparably and realization of new cutting orders is smooth and timely. Additionally, now we can easily prepare a stock of markers for the following days!

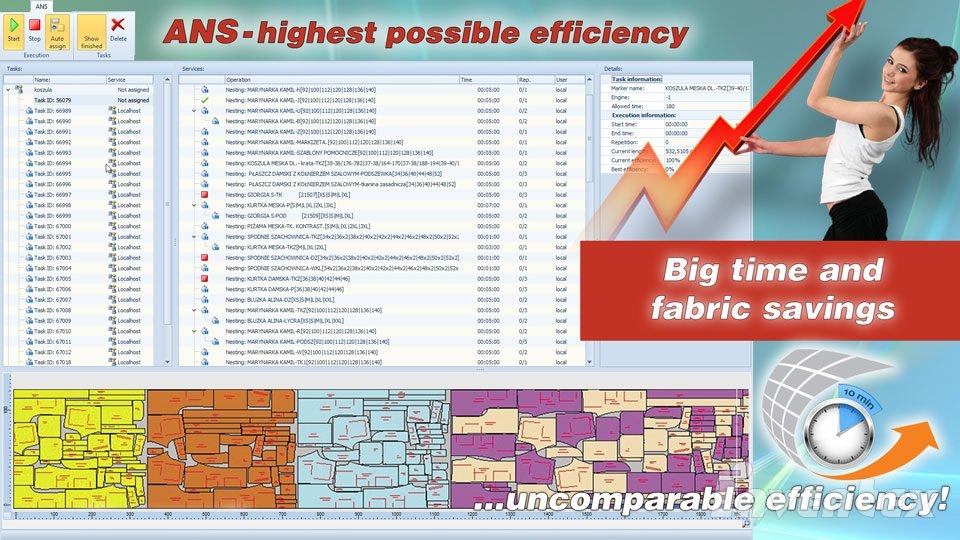

Innovative IMM (Intelligent Master Marker) module automatically. intelligently and in barely 2-3 minutes can create markers with highest possible efficiency and lowest fabric wastage. Systematic creation of such highly effective cutting markers in such a short time is impossible with manual methods. Fabric consumption during marker creation is constantly monitored. The system is handling perfectly checkered and striped fabrics, but also restrictions for fabrics with repeatable patterns. It’s possible to work efficiently with multiple simultaneously opened markers with vast range of possible modifications and data processing.

With the InvenTex system even the best cutting plan can be created much faster and optimized masterfully using intelligent InvenTex CutPlan module. Additionally you can obtain even up to 10% of fabric savings.

Thanks to the InvenTex system you can achieve a revolutionary change in functioning of your cutting room. Do not hesitate, it’s time for innovation and new technologies!!!

Advantages for the user:

- very easy to use and with short time of introduction to actual production

- automatic update of cutting markers after any changes made in construction module

- advanced modifications of patterns shapes, individual buffers, etc., directly in the MGS module

- fully customizable according to user’s needs, modern, ribbon-based user interface, with reconfigurable keyboard shortcuts and colors settings

- fully parameterized data export with output to printers, plotters or cutters, with comfortable automatic preview

- super fast graphics subsystem utilizing OpenGL technology, very high precision and displaying speed

- unlimited number of sizes, patterns, models and groups of patterns within one marker

- dynamic, scalable preview of created marker with unlimited undo/redo function

- quick return of investment and big savings in the following periods of time

Fast and easy markers creation

- new markers can be created easily by modern and intuitive Marker Creator tool

- additional “quick marker” function allowing to generate single markers from one fabric group

- very fast creation of new markers based on previously made ones, with easy modification of sizes and their quantities on the marker

- creation of markers based on models imported from other systems

- possibility to create multiple markers in one step, eg for a complete order

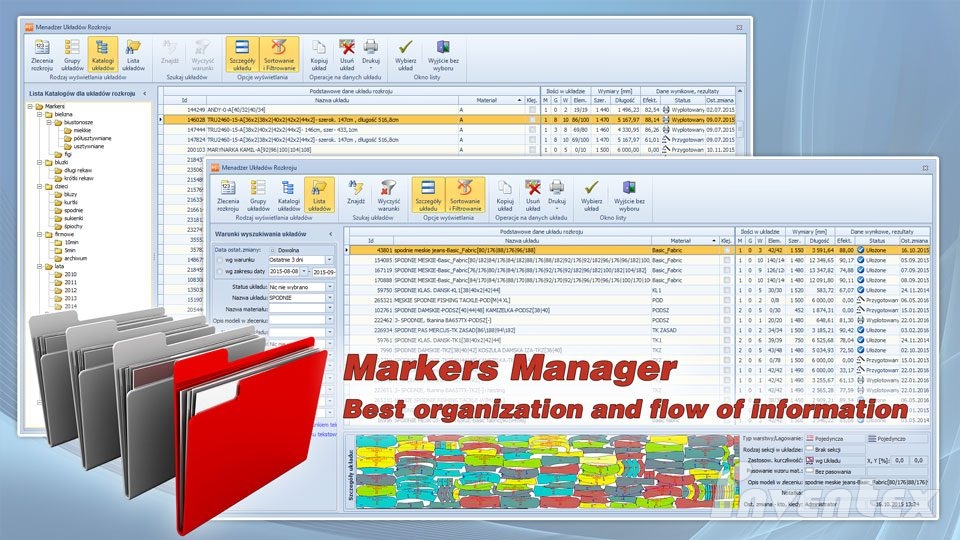

Managing of cutting markers

- Marker Manager allows to manage the markers in a very comfortable way, replacing generic, OS-level file handling dialog

- thanks to database usage InvenTex MGS provides the best methods to search for markers with lots of useful filters, parameters and search criteria

- visual access to complete information about selected markers, even before opening them, with consideration of current marker’s status

- highly effective grouping and cataloging of markers

- drag^drop function greatly simplifies cataloging

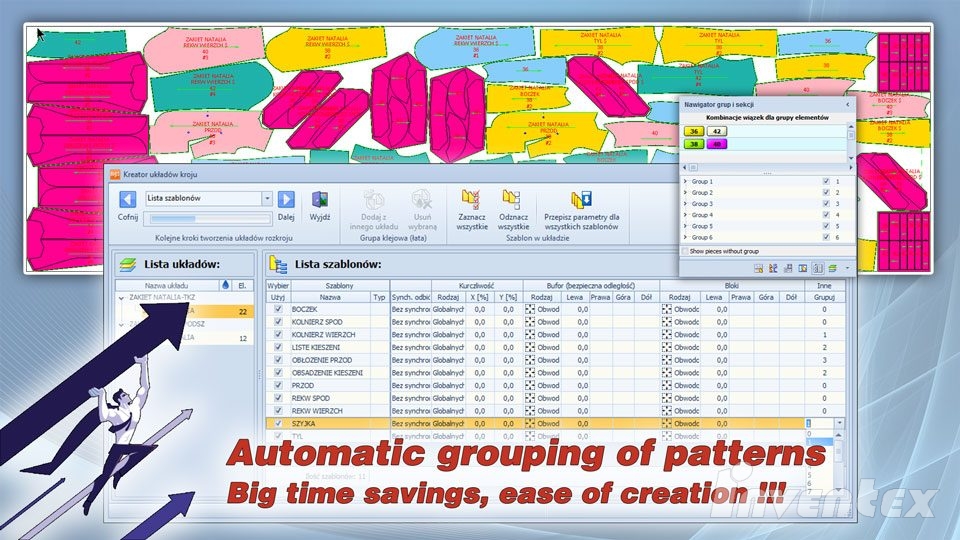

Automatic creation of groups

- one click creation of all patterns groups results in very big time savings

- default grouping rules and following construction settings

- assignment of patterns to certain group takes into consideration selected patterns and combinations for joined sizes

- additional restriction of max width or length of the group resulting from eg parameters of the fusing machine

- various methods for definition of group outline type, margin, block, grouping type, group’s description

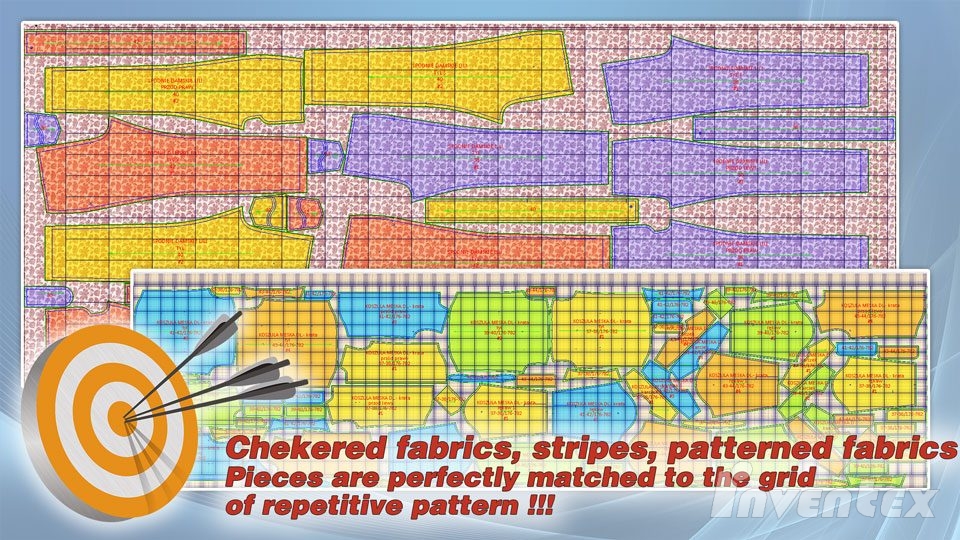

Markers on checkered fabrics

Best methods of nesting & aligning of elements to the pattern on fabrics

- creation and handling of markers for all types of patterned, checkered or striped fabrics

- visualization of pattern is displayed on elements and fabrics during markers creation and previewing

- possibility to create database with definitions and parameters of patterns

- flexible methods for the type and place of elements matching to the patterns on fabrics

- full support of elements matching to the pattern on fabric also in the InvenTex IMM automatic nesting module

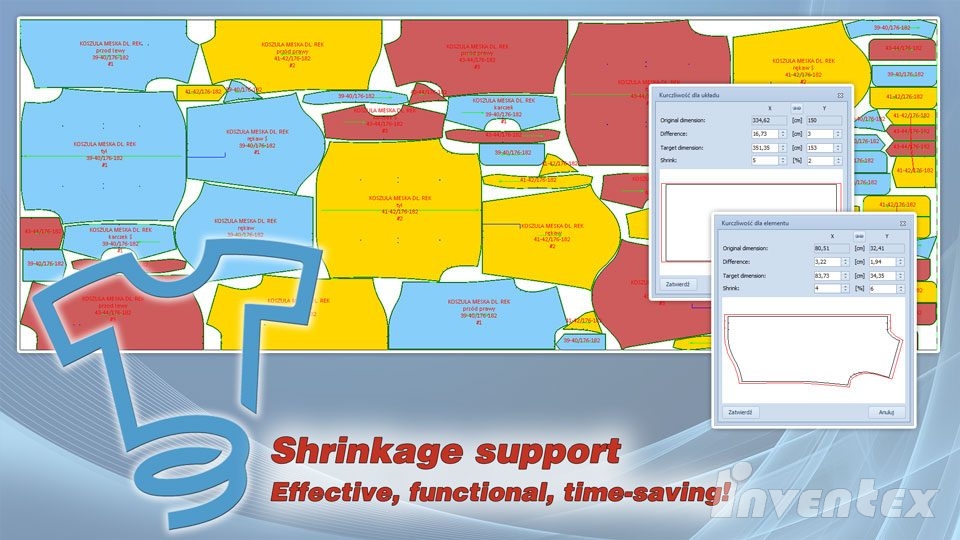

Very good shrinkage support

- it’s not necessary to prepare and scale patterns in the construction module

- possibility to define different shrinkage values for length and width of fabric, with restrictions for rotations of patterns

- support for global shrinkage value for the whole marker and individual shrinkage for for selected patterns, quick change of parameters

- easy method of shrinkage parameters calculation

- possibility to use shrinkage value defined for particular pattern in the construction module

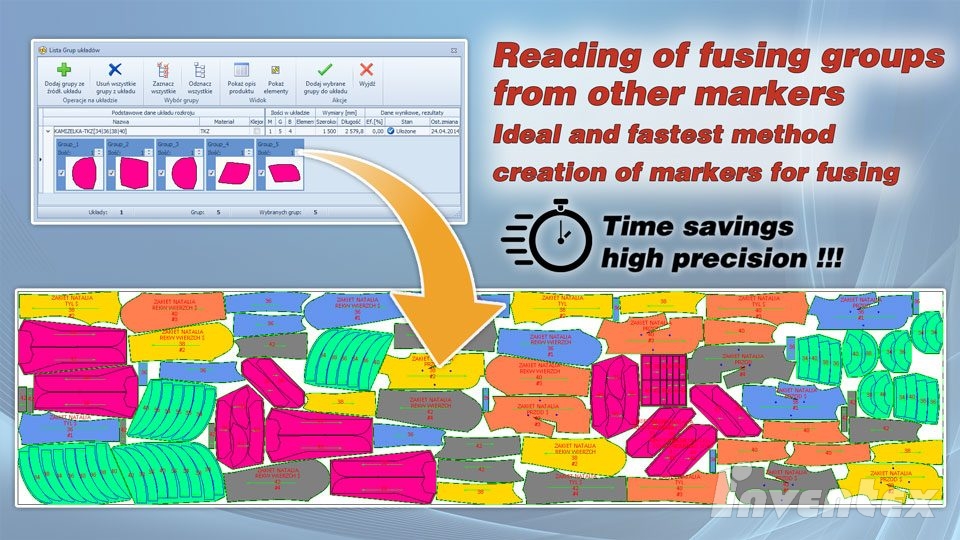

Very easy work with fused patterns

- very easy method allowing to move gluing groups from main to the fused fabric

- possibility to load gluing groups from multiple other markers

- high precision thanks to the integral, database connection of gluing groups with main markers

- easy to use interface facilitating opening of gluing groups from main markers, allows for their filtering and selection

- verification methods eliminating possibility of errors and lack of synchronization between fusing and main fabrics

Rotations and other restrictions during nesting

- precise interpretation of rotations and restrictions allows to create markers which will be always made in accordance to technological requirements

- big flexibility in definitions of required parameters for individual patterns within cutting marker

- possibility to use global parameters for a whole marker and individual restrictions and rotations for selected patterns only

- automatic verification of patterns nesting within marker, always according to given requirements and restrictions

Joining of cutting markers

- possibility to join several markers both along the length and width of a marker, with optional additional margin

- easy creation of new markers resulting from joining and mutual combination of short markers, including one or more sizes

- possible parallel print-out of two narrow markers as one utilizing full width of a plotter, eliminates the need of paper change

- visual preview of joining operation for selected markers even before their approval and saving of new marker

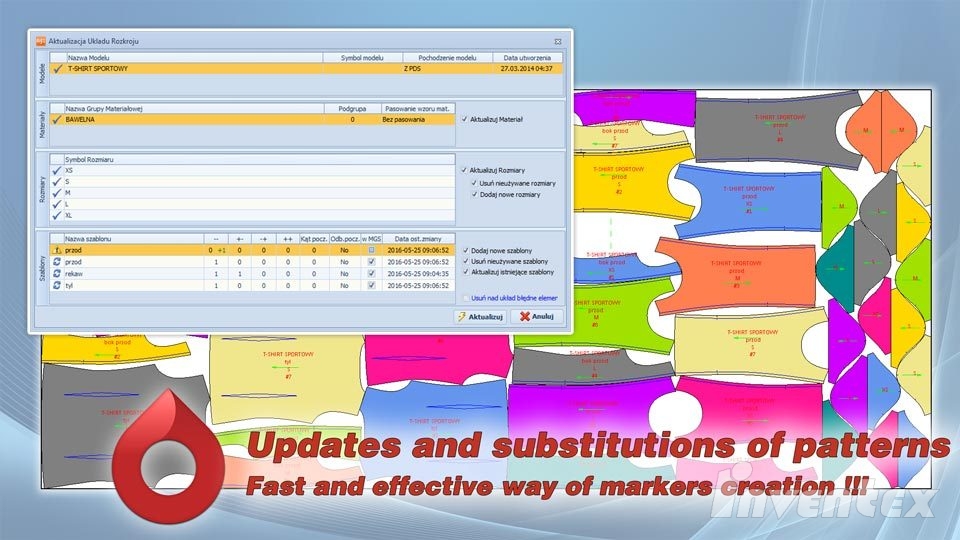

Updating of modified patterns in finalized markers

- comfortable and very useful function allowing to update patterns in ready to cut markers, eg after adding a notch or modification of undercut

- substitution possibility allowing to exchange models, sizes, or selected patterns for quick re-configuration of already finalized marker and storing it under a new name

- easy to use dialog window providing functionality necessary to perform updates of markers

- full integration with construction module provides automatic notification about eventual marker update if some of its patterns were modified

Excellent presentation of results

- printouts are the essence of a solution, their aesthetics and meritorical contents emphasize the highest usability value of the system

- they’re generated using the best available reporting solutions, clearly presenting created markers and results of optimizations

- printed documents assure better production organization and cutting costs control

- advanced tool allowing to modify existing reports or create new reports or summaries is also provided

Additional functionality of the MGS module:

- many markers can be opened in tabs and processed simultaneously

- constant, dynamic measurements of all marker’s parameters assures minimal fabric consumption and provides information about current status of the markers

- required quantity of patterns within one marker is automatically controlled and correct placement of patterns is fully controlled with nice visualization of the current stage

- creation of markers for fabrics which contain faults, lines of overlapping which are facilitating joining of fabrics during spreading

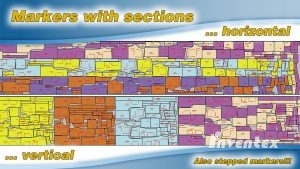

- possibility to place patterns within defined areas of the marker in so called sections (horizontal or vertical stripes), available are also stepped markers

- possibility to add new size to finished marker, additional model or additional components even from another model, to reduce fabric waste even further

- possibility to cut selected patterns within marker with automatic creation of required seaming allowances in order to reduce fabric consumption

- import of markers from other systems with possibility to edit and further optimize them

- support for all available on the market plotters and cutters