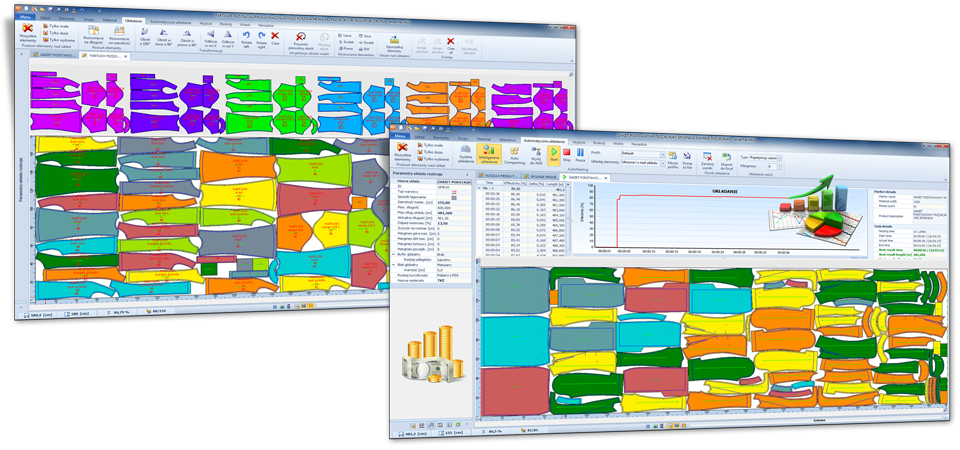

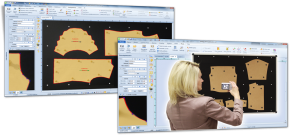

InvenTex Intelligent Master Marker (IMM) creates automatically, intelligently optimized cutting markers in just 2-3 minutes. Comparison tests confirm the highest efficiency among all currently available solutions. InvenTex IMM respects all given restrictions of acceptable patterns rotations, buffers between patterns, fusing groups, fabric width variations, fitting of checkered fabrics, nesting in horizontal or vertical sections, joining of manually nested blocks with automatic nesting. Each cutting marker optimized by IMM module, we can obtain further fabric savings of 1-5% minimum (in comparison to markers created in computer software, but using manual method, uncomparable speed in reference to manual method (2-3 min/marker), what results in a very quick return of invested resources. From now on you’ll be able to notice constant reduction of fabric consumption and money staying in the pocket. Scale of financial advantages depends on the type of production but it usually is several thousands Euro. Possible cooperation with any CAD and optimization of cutting markers created in other systems. Reduced fabric consumption without the need to buy and replace already implemented system which is used for construction and grading of patterns.

InvenTex IMM Inteligent optimal nested markers

Making of the best cutting markers in a very short time

Advantages for the user:

- very big fabric savings thanks to intelligent algorithms for markers optimization

- huge time savings thanks to full automation of the process

- highest efficiency which does not depend on experience and commitment of the operator

- elimination of delays, even during a maximum accumulation of orders

- server version can optimize markers also at night and over the week-ends

- very short return time of investment, continous additional profits in the future

Automatic nesting of all types of markers

- InvenTex IMM was designed in a way to assure 100% automatic marker nesting, even with the most advanced technological requirements

- has all functions necessary to support creation of markers made of difficult and advanced fabrics

- Shrinkage, fabric faults or requirement to nest patterns on shaded markers is not a problem

- Thanks to full integration with main InvenTex MGS module the IMM provides the highest possible functionality and assures optimization on the World-class level

Reduction of production costs

- only the module for highly-efficient creation of cutting markers can refund the whole investment in a short time

- automatically created cutting markers, always with lowest fabric consumption, can be achieved in 2-3 minutes

- comparison costs proved the highest efficiency among similar solutions available on the market

- the module cooperates with intelligent Cut Planer assuring most optimal planning of cutting operations based on the quantity and colors of ordered products

Markers of highest effectiveness

Automatic queuing is a key to effective work of the system

- Intelligent nesting algorithm allows to look for more optimized marker with each subsequent try, resulting in higher fabric savings

- Especially designed queuing method for automatic nesting helps to find best solutions assuring best computer time utilization in order to achieve required number of optimization attempts

- Possibility to work with multiple opened markers allows to create new nesting jobs, create new markers and print finished markers, all in parallel way

Utilize power of your computer

Thanks to multi-core processors with multithreading capabilities you can easily achieve biggest time and money savings

- Intelligent, automatic nesting is the result of calculating very big number of mutual combinations of patterns placement, in shortest possible time by means of efficient algorithm

- The key to obtain best possible results is a suitable computer with high processing power

- Using multithreading processor and IMM Pro Plus Multicore allows to make several times more attempts to find a solution during the same time period, allowing to achieve incomparably higher fabric and work time savings

- IMM will utilize multiple processors and 8, 16 or more of its threads, also in Intel® Xeon® processors

InvenTex IMM is available in several versions, check the possibilities …

– choose the solution which will be the best for you:

InvenTex IMM - Professional

Most often chosen professional version of the InvenTex IMM module, based on new generation of the advanced intelligent auto-nesting algorithm. Allows to obtain even up to 5% of additional fabric savings in comparison to markers created interactively or in standard version of automatic nesting.

PROFESSIONAL version, thanks to price/effectiveness of created markers ratio is a very good choice for manufacturers for whom the fabric savings and shorter markers preparation time are important parts of production costs.

Moreover the option of intelligent, automatic creation of optimized markers for patterned, striped or checkered fabrics is available at the price, without additional costs.

InvenTex IMM - Professional Plus

Greatly improved version of the InvenTex IMM module, without modifications in visual layer, while newest generation of intelligent, automatic nesting algorithms allow to achieve even up to 2% of additional fabric savings in comparison to the PROFESSIONAL version. Introduced additional optimization allows to obtain best results in even shorter time.

PROFESSIONAL PLUS version is the perfect choice for manufacturers for whom additional savings in fabric consumption and shorter marker preparation times are most important.

Moreover the option of intelligent, automatic creation of optimized markers for patterned, striped or checkered fabrics is available at the price, without additional costs.

InvenTex IMM - Professional Plus MultiCore

The best version of InvenTex IMM module, based on the algorithms used in PROFESSIONAL PLUS version. Additionally in this version newest generation of technologies allowing to utilize multi-core processors were used allowing to run multiple, parallel processing simultaneously providing much more additional patterns placement combinations. Used technologies result in following 1% of additional fabric savings in comparison to PROFESSIONAL PLUS version. Installation of the software on 8 or 16-core processor and usage of InvenTex ANS allows to obtain even higher savings.

PROFESSIONAL PLUS MULTICORE version is the best choice for manufacturers for whom a minimal fabric consumption and optimal working time are most important.

InvenTex IMM - Patterns Compacting Module

IMM Compact it’s a new product, an extension designed especially for the InvenTex IMM module. It’s meant for even better compaction of nested markers to achieve smaller fabric consumption. The biggest savings are possible for cutting markers with big quantities of small patterns eg lingerie. With IMM Compact module it’s possible to optimize ready/finished markers created manually, interactively or automatically. Additional algorithms allow to “squeeze” nested patterns so that their more optimal position will be found without changing their mutual positions.