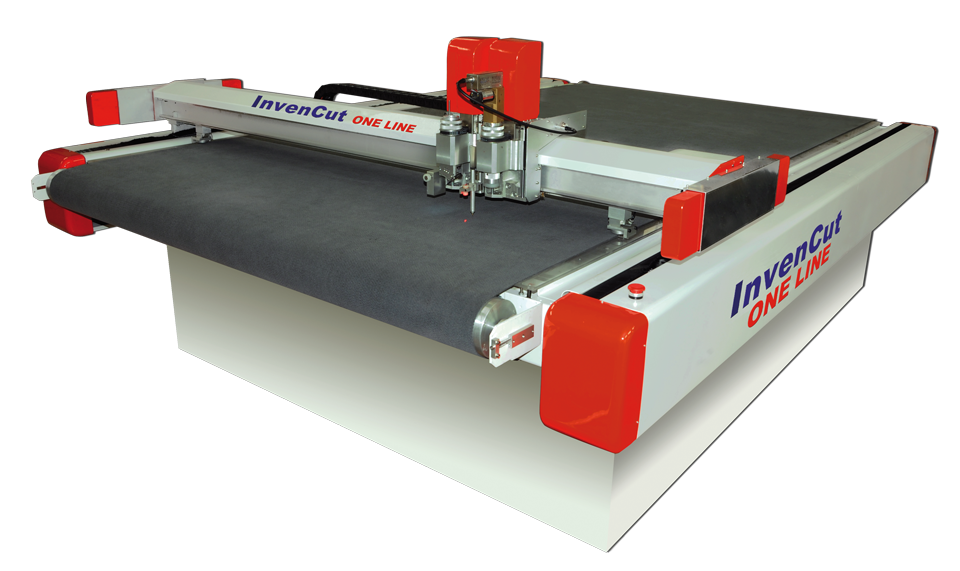

InvenCut ONE LINE Cutting plotter– a multi-purpose cutting machine for single layer cutting, creasing and routing of material . Most advanced solution used by very wide spectrum of end users, for almost all types of materials. InvenCut ONE LINE cutting plotter is used by manufacturers of apparel, furniture and automotive upholstery, cutting of technical and composites materials, in advertising and packaging industry, bags and suitcase, gaskets, and many more.

Very wide range of materials for cutting:

Natural and technical fabrics: textile, knitwear, nonwovens, carpet materials, synthetic leather, vinyl, all types of foam and sponge materials, foils and laminated materials, glass, carbon and aramide fibres and pre-pregs, different types of thermoplastic materials, rubber coated materials materiały and insulating materials, cardboard and corrugated boards, etc.

| InvenCut ONE LINE series | ||

|---|---|---|

| Model | TC-2516 | TC-LxWx* |

| Max. cutting width | 160 cm | 80 – 320 cm |

| Max. cutting lenght | 250 cm | 80 – 320 cm |

| Cutting hight [max.] | 1 layer 50mm | |

| Cutting speed [max.] | 1,5 m/s | |

| Cutting acceleration [max.] | 10 m/s2 /1g | |

| Cutting precision | 0,1 mm | |

| Noise level | < 73 dB | |

| Power requirements | 3-phase 400V+N / 50Hz | |

| Vacuum pumps range | 4 – 13 kW | |

| Compressed air requirements | 6 bar | |

| Working temperature | 10 – 40 oC | |

| Relative humidity | relative 30-80% (without condensation) | |

*Lx -max. cutting window lenght, Wx – max.cutting width

End user benefits:

- Maximum output – cutting underlay of the machine is at the same time a conveyor belt used to transport cut out elements from the cutting area– possibility of cutting and collecting of elements at the same time

- One person operation, depending on production profile, machine may substitute hand work of many people

- Compact size of the cutting space – cutter and the unwinding system eliminates long spreading tables

- Highest precision of cutting elements – easier work in the stitching department – highest quality of work

- Synchronization of cutter and unwinding machine, ensures production flow and feeding accuracy

- Wide range of cutting tools, compatible with world known standards

- Effective vacuum system ensuring proper hold of materials to be cut on the surface of the cutter, no need of additional covering of the material with foil

- Relatively low cost of maintenance of the machine, lowest cost of operation cutting per element

- Wide range of cutting area sizes: 80-320cm, made to measure for all types of production needs

- Simple software, many useful functions like cutting pause, conveyor movement of knife calibration

InvenCut ONE LINE cutter offers innovative modular construction. This feature allows to choose best configuration, so the customer will order components which are absolutely necessary for his production profile. Any time, the cutter can be re-configured adding new options .Cutting size can be configured according to the customer needs when ordering. As a standard feature, the cutter is configured with two cutting modules, where each module can be fitted with different cutting tools described below. This feature allows to perform cutting operation using two different types of tools controlled by software, without need of changing them manually. This allows all cutting operations to be done faster and easier, ensuring highest accuracy and in proper cutting order according to types of lines used.

The two standard cutting modules (cutting heads), can be fitted with two different cutting tools, according to current production needs. Wide range of cutting tools and the advanced technology involved in their production, ensures highest quality of cutting output. In order to change the current tool, you do not need to use any special tools like screwdrivers or spanners. InvenCut ONE LINE cutter offers, all possible tools available to cutting plotters on the market. These tools are produced according with highest standards and ensure durability and precision. This system will allow us to be able to have access to wide range of knives available in the market.

UCT – Universal Cutting Tool (Tangential Knife)

POT – Pneumatic Oscillating Tool

RT – Routing Tool

V-CUT – dragged knife with adjustable cutting angle

CT – Creasing Tool

KCT – Kiss-Cut, for cutting labels

EOT – Electric Oscillating Tool and Power EOT

DRT – Driven Rotary Tool with 10-faced rotating knife