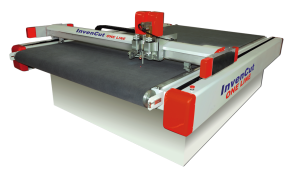

Important technical features of the cutter:

- Cutters from the MASTER LINE series represent solid and stable construction of the machine

- Key components of the cutter are produced by the well reputable manufacturers

- Drives of all X, Y, Z i C axis use well known sero motors by Parker, USA

- Automatic, programmable sharpening system using two sharpening discs for continuous sharpening

- High precision cutting– same shape of cut elements in all layers

- Automatic knife position, according to current width of the sharpened knife

- Conveyorized bristle table with high quality brushes, long life and durability

- Brush self-cleaning system during cutting with separate waste container

- Drill device for drilling holes as a standard feature

- Additional active foil covering device for cut elements, standard feature

- Conveyorized collection table 2 meters long, convenient way of collection of cut elements

- Advanced but simple cutting head construction, trouble free performance of the device

- Very innovative construction of the cutter, easy access to all serviceable parts of the machine