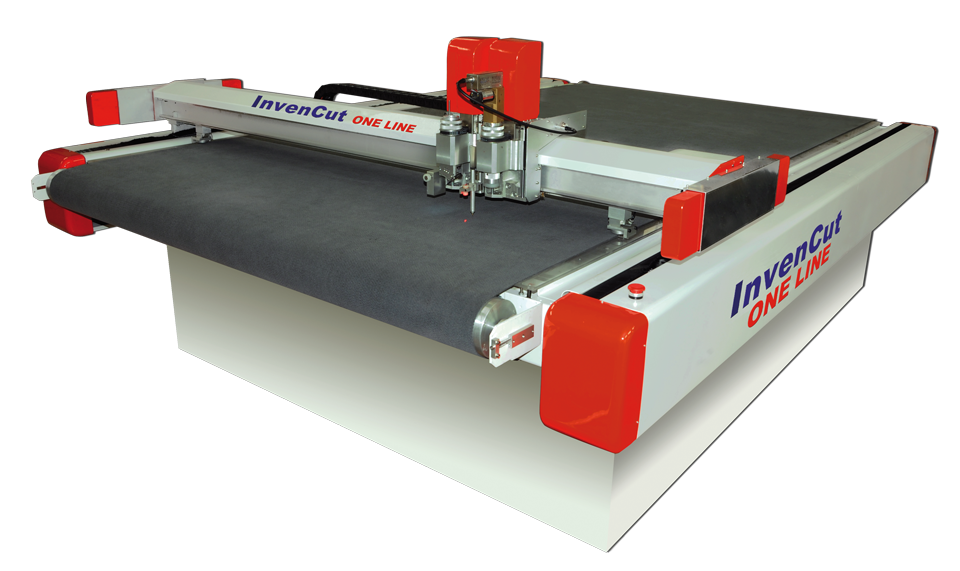

InvenCut ONE LINE Cutting plotter– a multi-purpose cutting machine for single layer cutting, creasing and routing of material . Most advanced solution used by very wide spectrum of end users, for almost all types of materials. InvenCut ONE LINE cutting plotter is used by manufacturers of apparel, furniture and automotive upholstery, cutting of technical and composites materials, in advertising and packaging industry, bags and suitcase, gaskets, and many more.

Very wide range of materials for cutting:

Natural and technical fabrics: textile, knitwear, nonwovens, carpet materials, synthetic leather, vinyl, all types of foam and sponge materials, foils and laminated materials, glass, carbon and aramide fibres and pre-pregs, different types of thermoplastic materials, rubber coated materials materiały and insulating materials, cardboard and corrugated boards, etc.