InvenTex PDM (Product Data Management) it’s an excellent tool allowing for global management of all information generated during production and technical documentation of a product. Starting from general properties, through detailed description of product’s components, technical sketch, description of applied technology in particular sections (cutting, sewing, finishing), fabrics and additional specifications, size sets – all these elements assuring necessary control on product’s specification, its production and management. Production process is described as a list of subsequent operations accompanied by time necessary to perform them. In the InvenTex PDM można it’s possible to create and manage multiple versions of the same model.

InvenTex PDM is something more than just the software – it’s an implemented idea of integration and management of all aspects of the product. Fast and always up-to-date information, gathered in one place it’s a key element of production management. InvenTex PDM was designed also with the concept of group work in mind, where it’s installed on many workstations working together within one computer network. InvenTex PDM brings time and money savings, allowing to obtain great level of organization and to create the best available bank of information about products.

Advantages for the user:

- Complete product information gathered always in one place

- Full specification of the product: descriptions, technical sketches, drawings, list of operations and instructions, list of components, tables with products parameters, initial calculations

- Creation of technological folder with printings in various configurations

- Increased production capabilities, higher quality and reduction of communication errors

- Full control of the production process thanks to always up-to-date information

- Support for sales and negotiations with tools for basic calculations

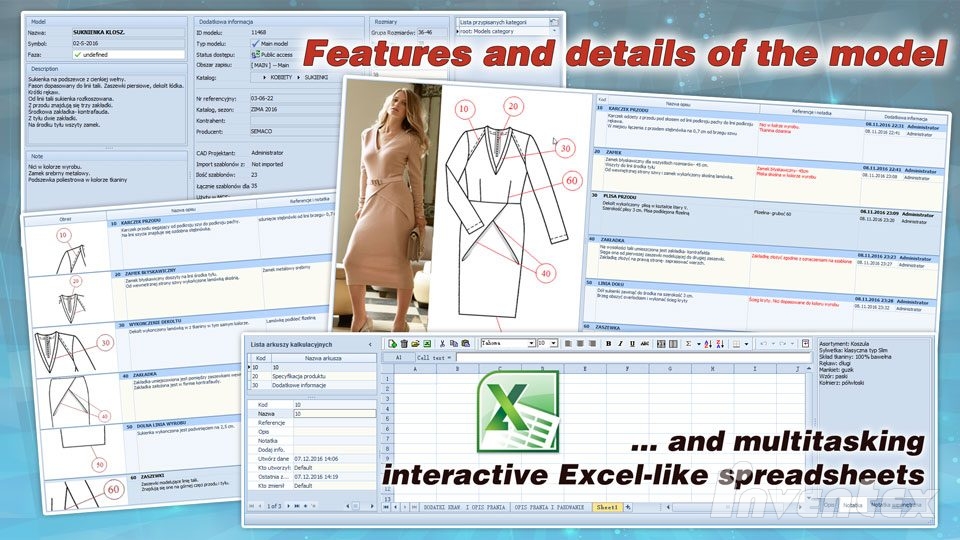

Technological descriptions

Tools for advanced technological documentation

- creation of basic description for the model file, available in all modules of the InvenTex system

- definition of product features with short technical description for each given feature, possibility to assign default features speeds-up and organizes entering of information

- detailed technological descriptions for selected details or operations, possibility to add picture to each item

- possibility to create individual documentation by using spreadsheets similar to Excel, unlimited possibilities of adding and exchanging information

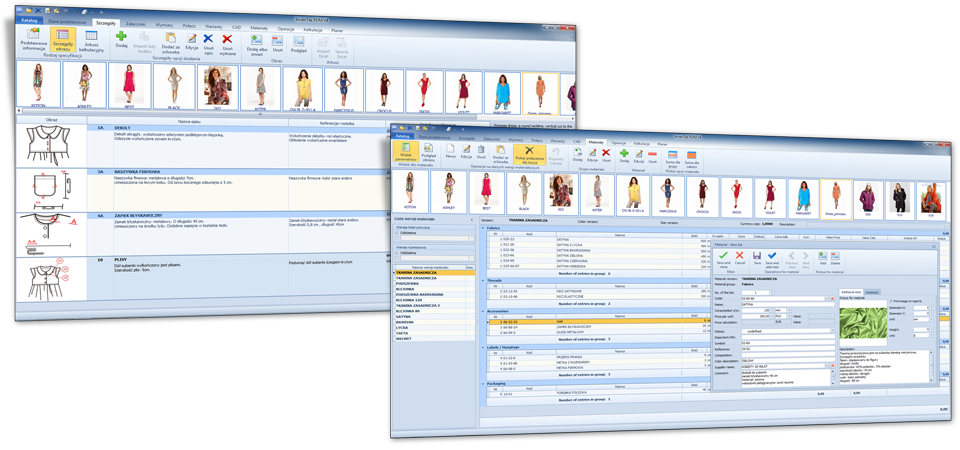

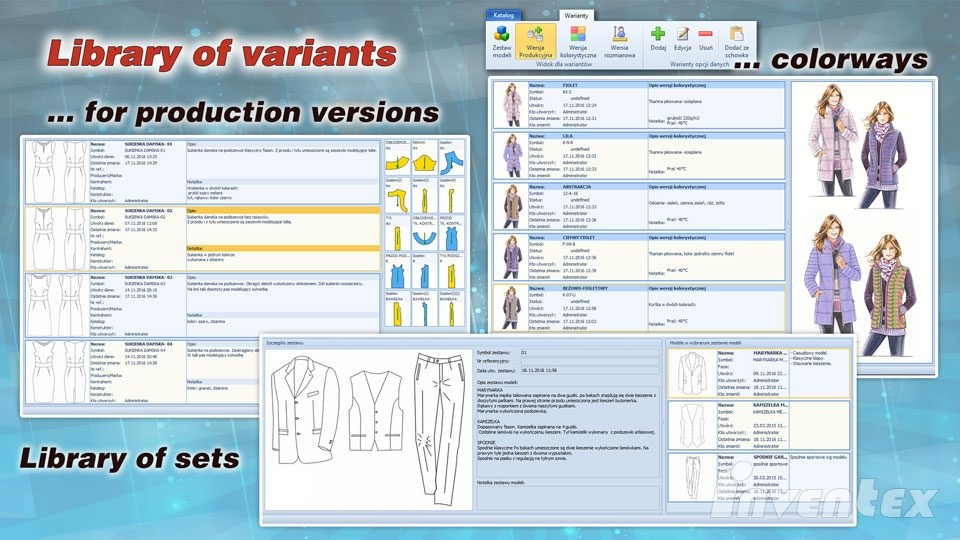

Variants with different colors of the model

Effective management of multiple variants of model finish

- possibility to define color variants for each production model

- organized directory of model variants it’s a base of good management and better product information flow

- for each color variant of the model it’s possible to create a list of fabrics and accessories dependant on particular color

- visually appealing presentation of available color variants

- possibility to create and store information about products, utilized internet services or e-shops

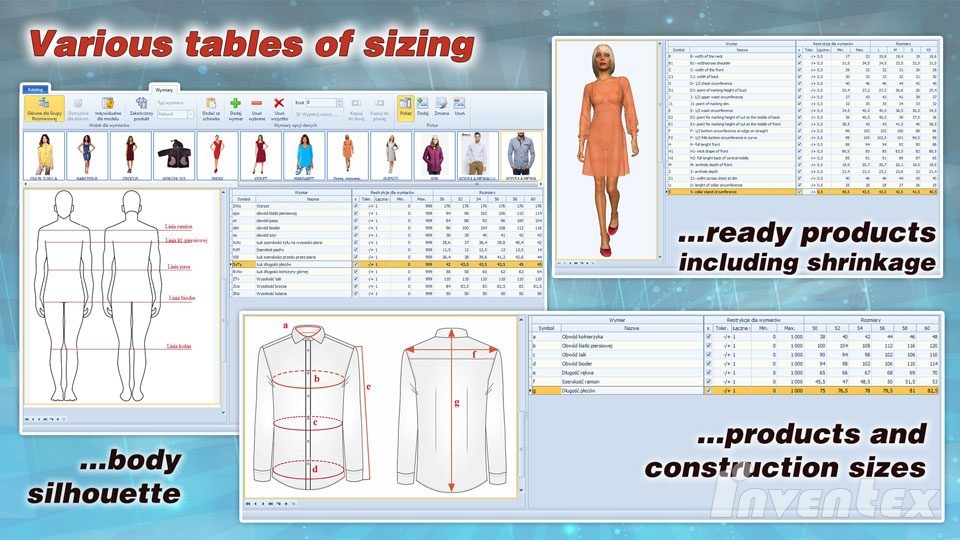

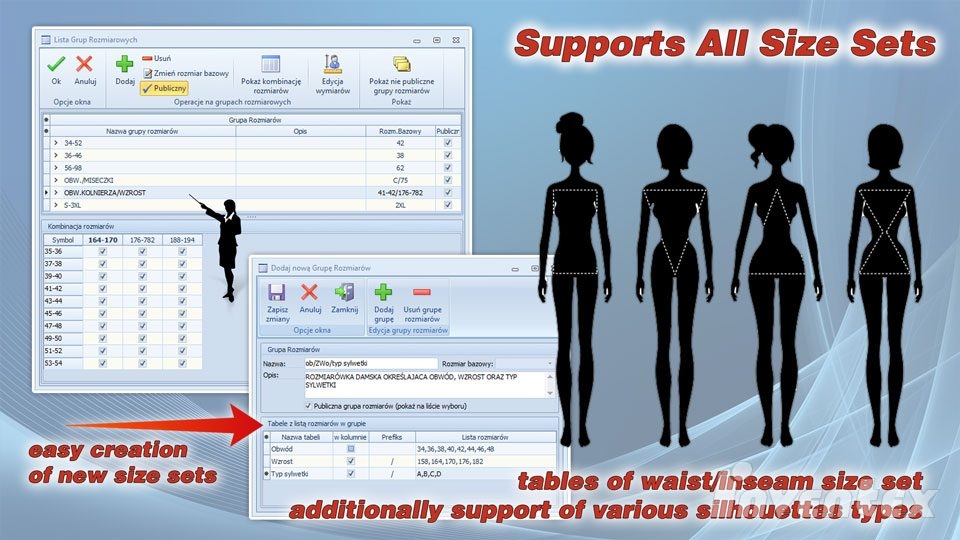

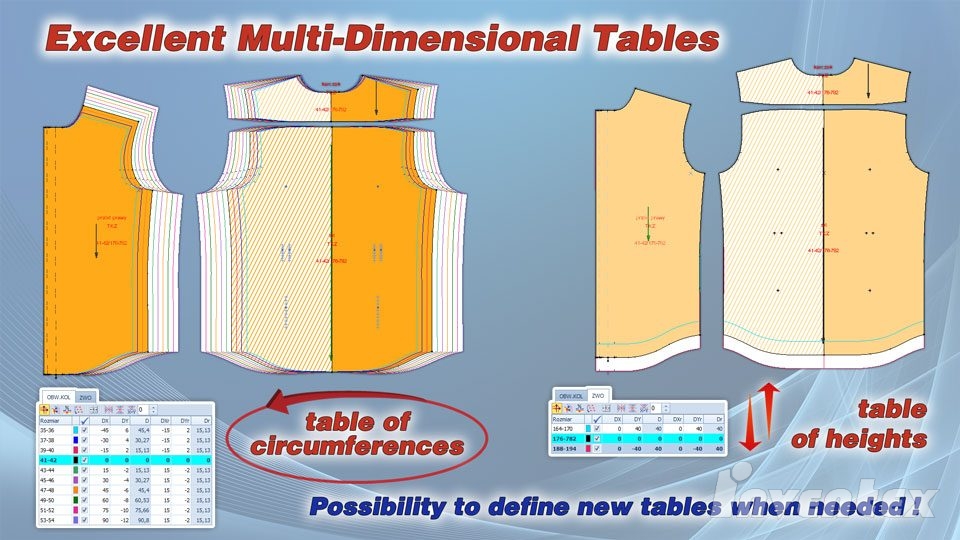

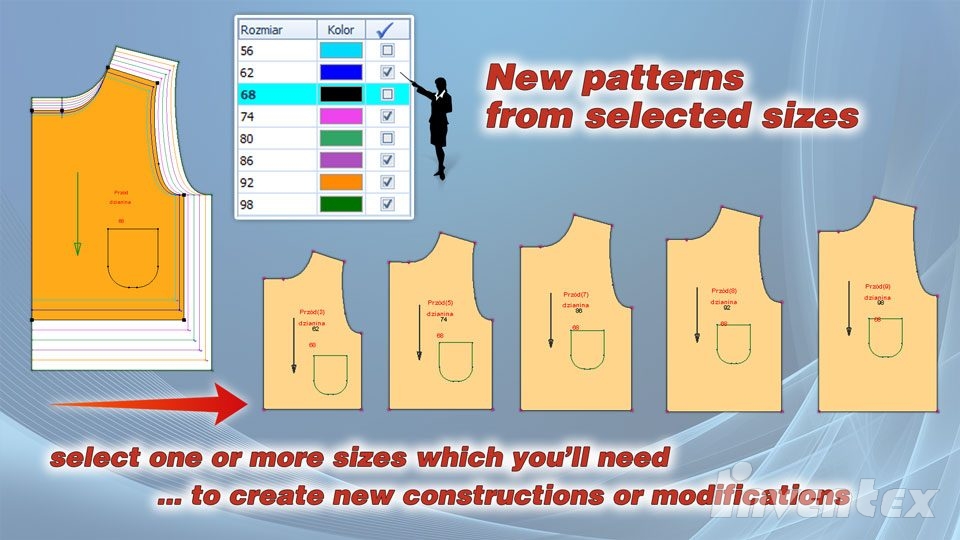

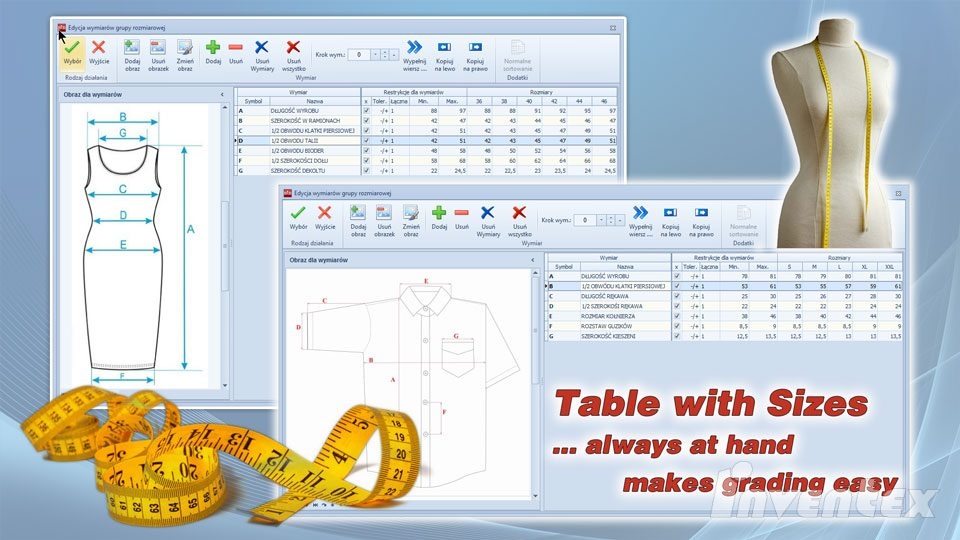

Size sets

Control and management on multiple size tables for chosen model

- each next model has one or more comfortable to use tables with body measurements or dimensions of a ready product (eg before and after washing)

- defined sizing tables are also defined and can be edited in different modules of the system, eg PDS – constructions or PGS – grading

- to each of the size sets it’s possible to assign one or more sketches with specification of its location also for subsequent sizes

- additionally there are tools for verification by physical measurements of finished products dimensions with possibility of reporting them back

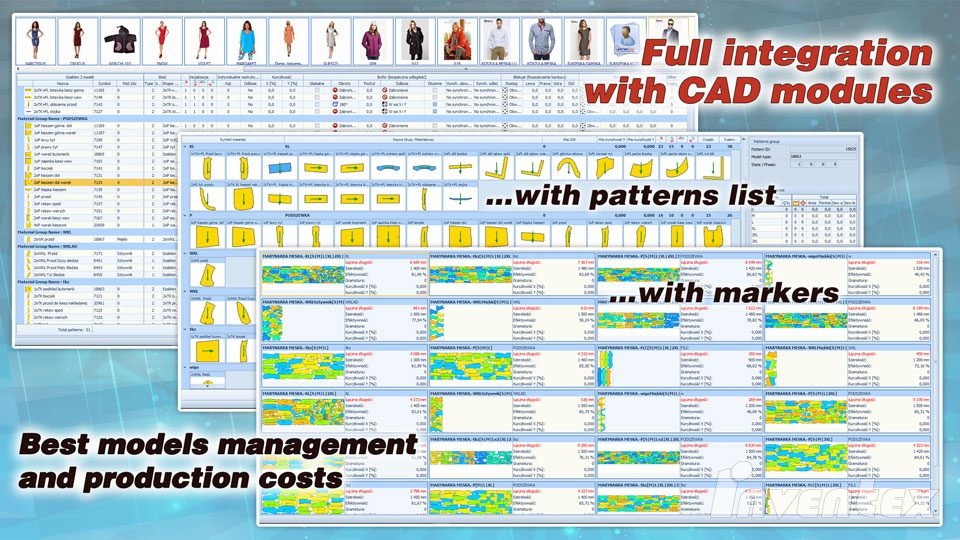

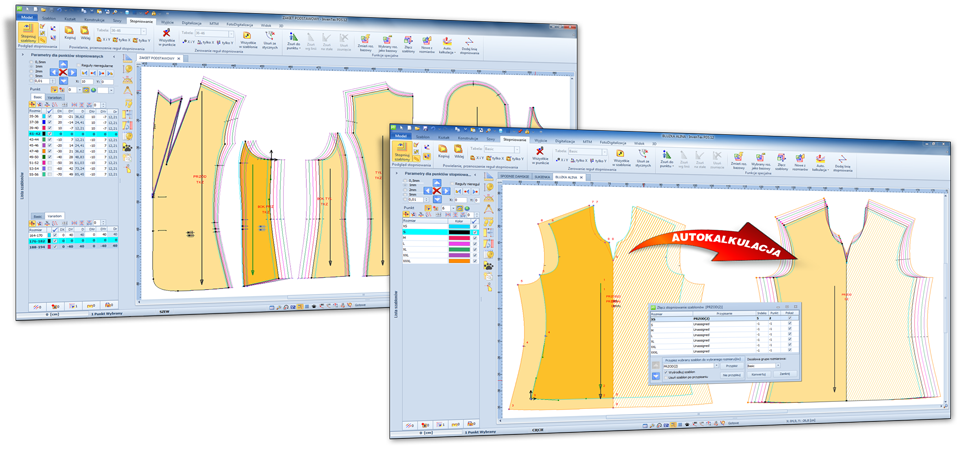

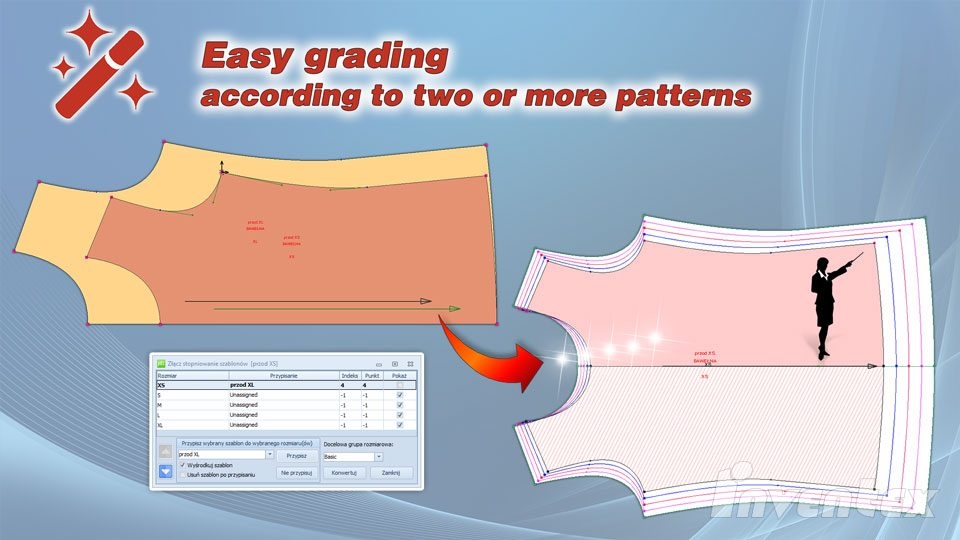

Full CAD system integration

Best sharing of information with construction and cutting room departments

- integration with PDS&PGS modules gives many key information about patterns utilization of a model, providing data for calculations

- connection with MGS&ICP allows for cutting and fabric usage information sharing, facilitates fabric consumption calculation, allows for markers grouping

- mutual exchange of data between CAD modules allows to obtain better organization of work, facilitates transferring of the results and allows to take better decisions during product management

- all necessary information are stored together in one database providing very good methods of searching for information

List of fabric costs

Management of fabrics, components and accessories

- allows for a definition of the key element of each product which is a list of fabrics and accessories needed to produce finished product

- the list can be divided into groups and cost categories resulting in precise qualification of specific parameters, eg fabric calculation which is calculated differently than thread consumption

- possibility to create an internal library with all additional technological information

- to each item on the fabric list it’s possible to assign a picture

- can be integrated with an external file of available fabrics

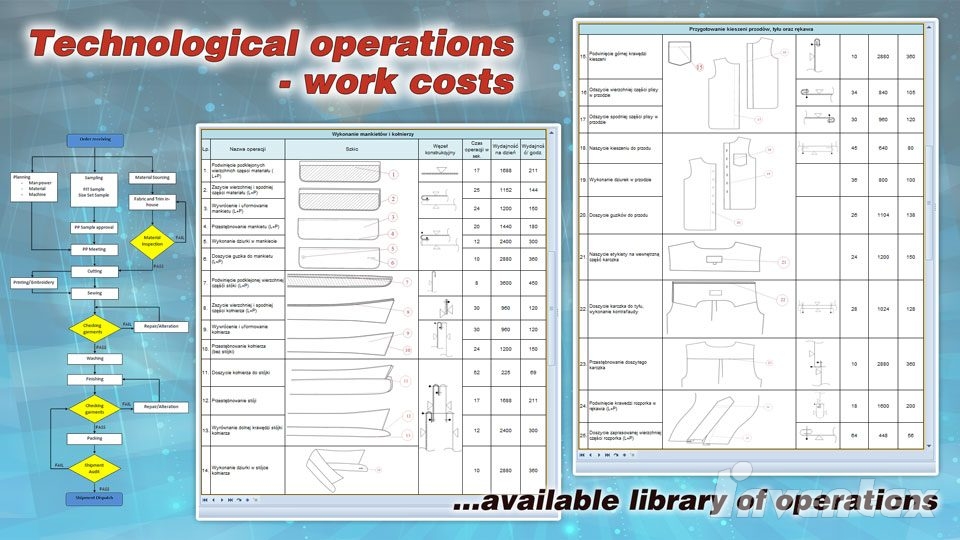

List of operations and their costs

Management of production operations and activities

- list of operations performed during production process is a very important element of each product specification

- it can be divided into groups and departments of the company allowing to improve calculation of costs and time or parameters of the process

- additional possibility to create an internal file of operations containing database of times or definitions of operation costs

- it’s possible to add picture to each item on the operations list

- can be integrated with an external file of available operations

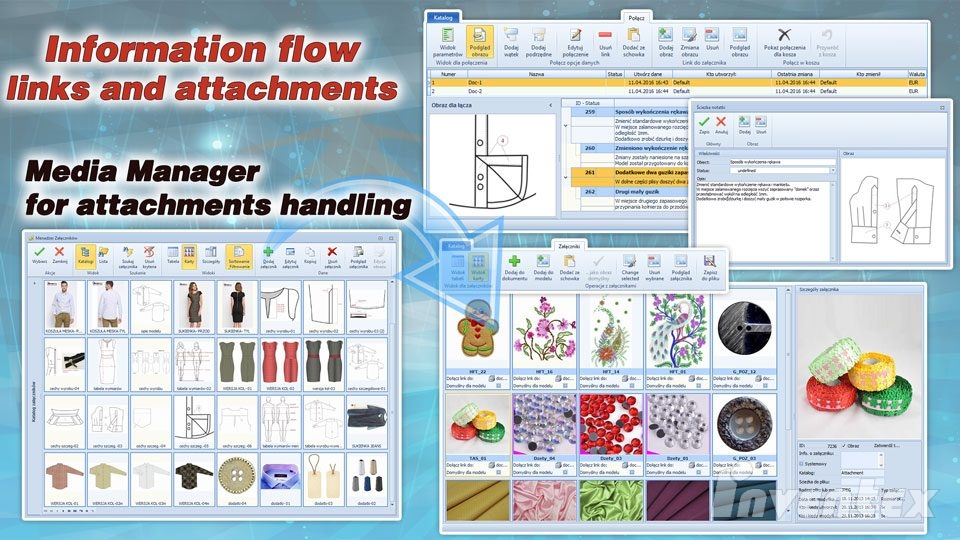

Attachments and links to information

Effective connection between models, multimedia, files and hierarchical links

- attachments are most popular and comfortable method of adding and extending information and descriptions

- InvenTex PDM supports all commonly known file formats for storing images, provides built-in tools for their previewing and edition

- Media Manager facilitates cataloging and managing of big quantity of files and multimedia content stored in a database

- hierarchical links with additional pictures stored in a tree data structure are a perfect way of dynamic data exchange

Printouts, technological catalog

Creation and printing of a professional technological documentation

- printouts are the essence of a solution, their aesthetics and meritorical contents emphasize the highest usability value of the system

- they’re generated using the best available reporting solutions, clearly presenting created markers and results of optimizations

- printed documents assure better production organization and cutting costs control

- joined printouts from various available files allows to create a technological catalog

- additionally an advanced editor provides tools for creation of customized reports and summaries

Available versions of the InvenTex PDM software

| Functionality of selected version: | COMPACT* | ESSENTIAL | PRO | EXPERT |

| Advanced cataloging and searching for models in the database | √ | √ | √ | √ |

| Creation of file with basic information about model | √ | √ | √ | √ |

| Creation and management of the attachments assigned to the model | √ | √ | √ | √ |

| Dynamic categories in tree data structure | √ | √ | √ | √ |

| Support of multiple production versions | √ | √ | √ | √ |

| Color variants of a model and its construction variants | – | √ | √ | √ |

| Completion and management of models in sets | √ | √ | √ | √ |

| Definition of features and detailed technological model descriptions | – | √ | √ | √ |

| Individual definition of information card in form of a spreadsheet | – | – | √ | √ |

| Size sets for body silhouette and dimensions of the model | √ | √ | √ | √ |

| Management and control on finished model, shrinkage support | – | √ | √ | √ |

| Lists of patterns used in a CAD system (integration with the PDS module) | –** | √ | √ | √ |

|

Lists of markers created from selected model (integration with MGS module) |

–** | √ | √ | √ |

| Hierarchical linking of information and technical descriptions with pictures | – | √ | √ | √ |

| List of fabrics and model elements with material costs summary | – | – | √ | √ |

| List of production operations for a model with work costs summary | – | – | √ | √ |

| Management of a file with all fabrics and components available in the database | – | – | – | √ |

| Management of the file with all operations available in the database | – | – | – | √ |

| Calculation of model costs considering all variants of the model | – | – | – | √ |

| Integration with a planner module and the timetable of performed operations | – | – | – | √ |

*InvenTex PDM in Compact version is built-in into CAD modules and it’s an integral part of the PDS and MGS modules **This functionality available directly in CAD modules (does not applicable to the integration of PDM with the InvenTex CAD)