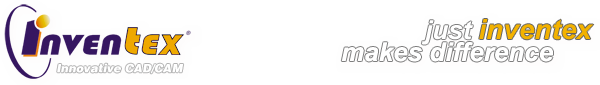

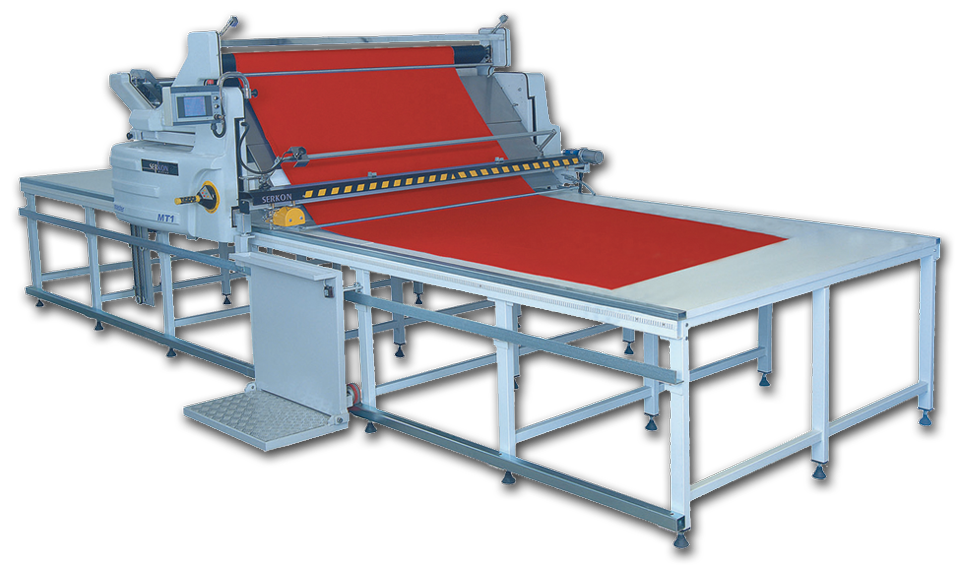

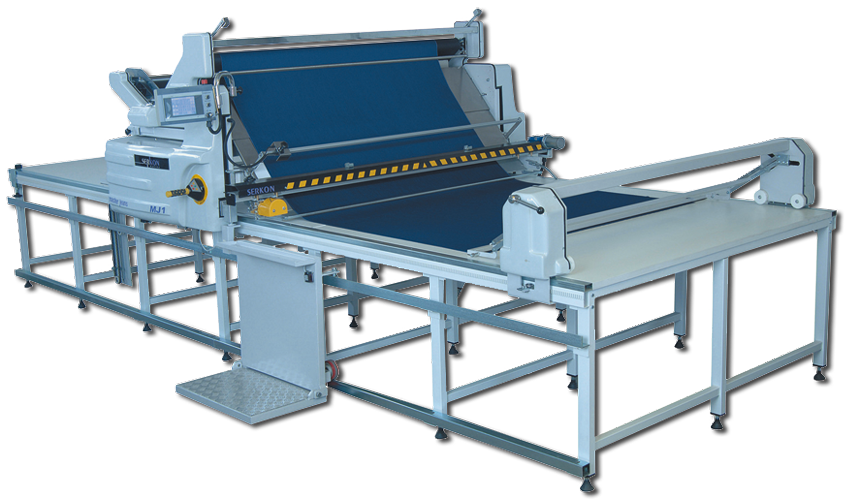

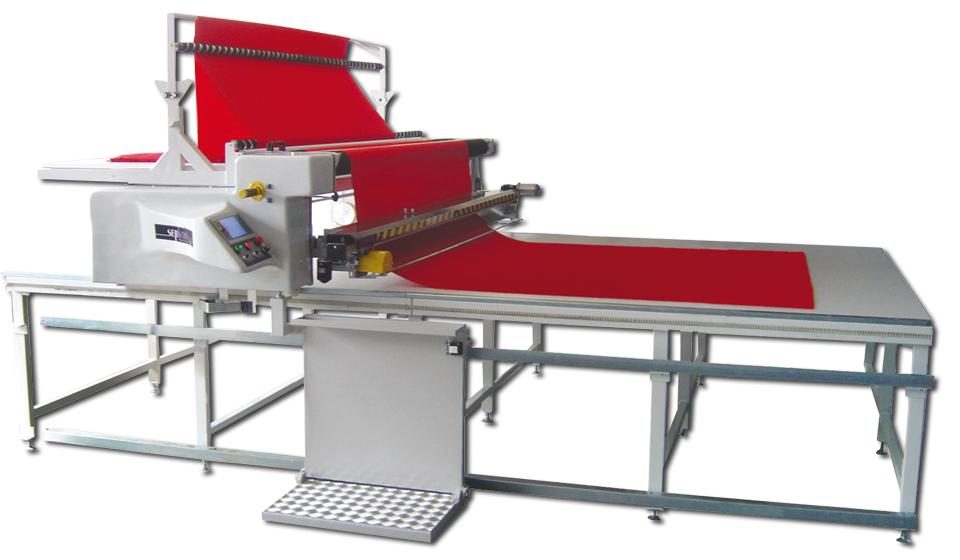

Automatic spreading machine enables us to spread wide range of used materials: starting with thin fabrics, stretchy and difficult to work with, through heavy materials like for example jeans material. Machine is equipped with conveyorized cradle, all wheel drive, operators platform and easy in use touch screen operator’s panel. Available wide range of spreading width machines ranging from 160 to 240 cm working width.

Important technical features:

- Automatic fabric edge control system

- Dynamic control of tension of the material

- Tensionless spreading system with end of material pressing bar or without

- Automatic cutoff of each layer of spreaded material

- Special device for zig-zac spreading with two press bars at both ends, standard feature

- On demand, the machine may be delivered with special equipment enabling to spread folded material (from pallet) or tubular knitwear material

- Possibility of work in manual and automatic mode

User advantages:

- Significant increase of possibility of spreading and unwinding of textile materials

- High quality and accuracy of work thanks to the automatic edge control system

- Uniform quality of spreading all length of markers, limited only by the length of spreading table

- Practically no limits in length of spreaded markers, like in manual spreading

- One man operation – cutting cost at increased output

- Possibility of fully automatic mode, without of attention of the operator

- Increased output also with short markers – cradle of the machine ensures easy load on and load off operation

| InvenSpread MN1 – Main technical parameters | |

|---|---|

| max spreading height with cutting unit (cutting of subsequent layers) | 250mm |

| max spreading height with zig-zag unit | 220mm |

| max spreading height with tubular unit | 200mm |

| max working width | from 160 to 240cm |

| max diameter of fabric roll | 450mm |

| max weight of roll | 120kg |

| max spreading speed | 100 m/min. |

| voltage and power | 2,5kW/ 220-240V |