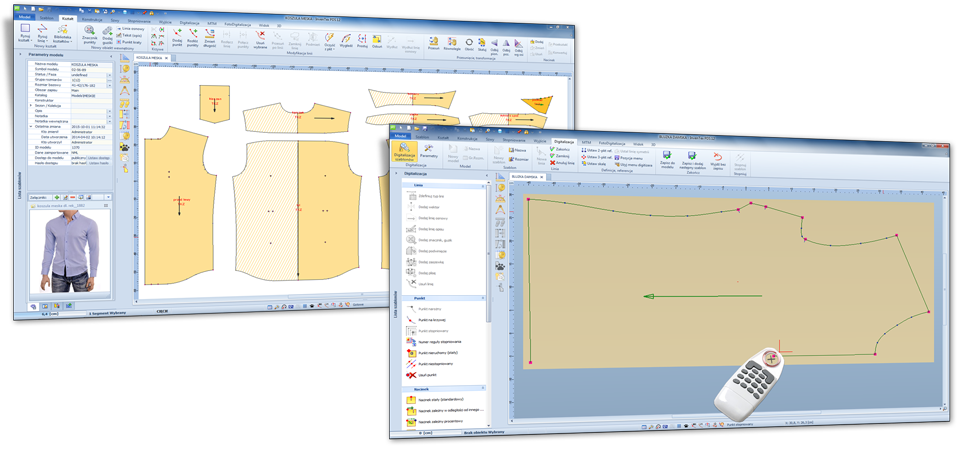

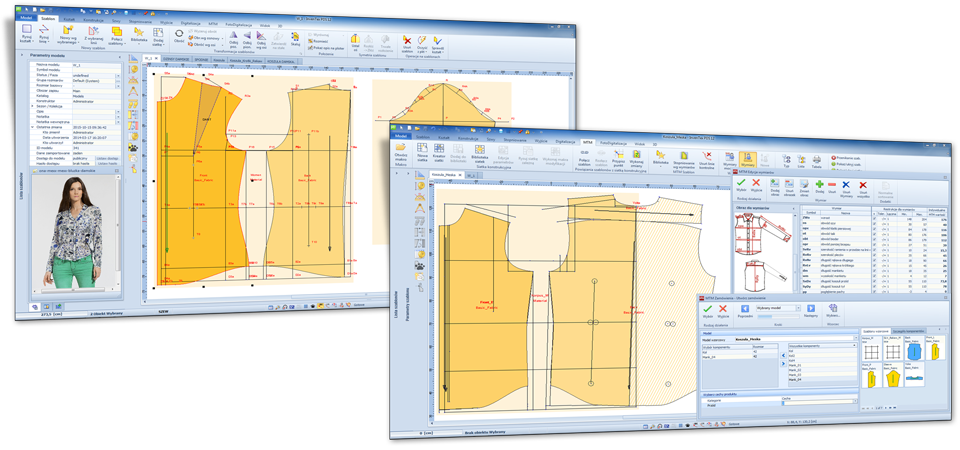

Intuitive and creative work with patterns!

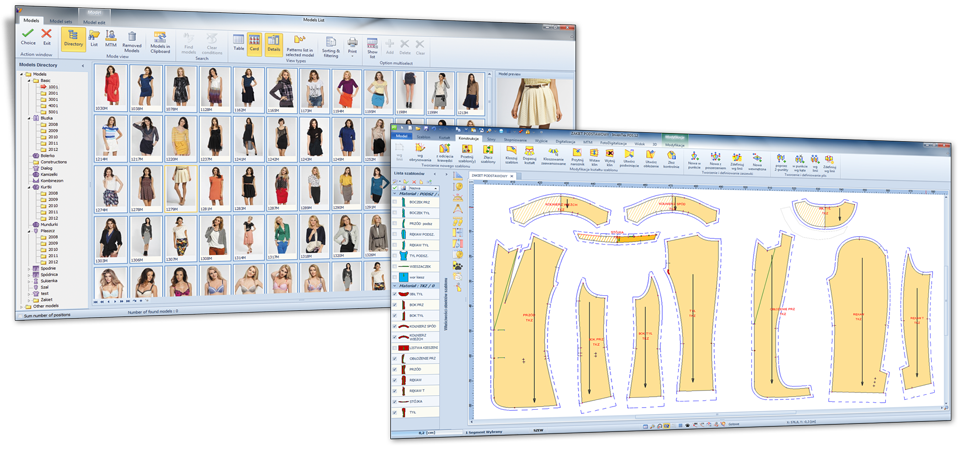

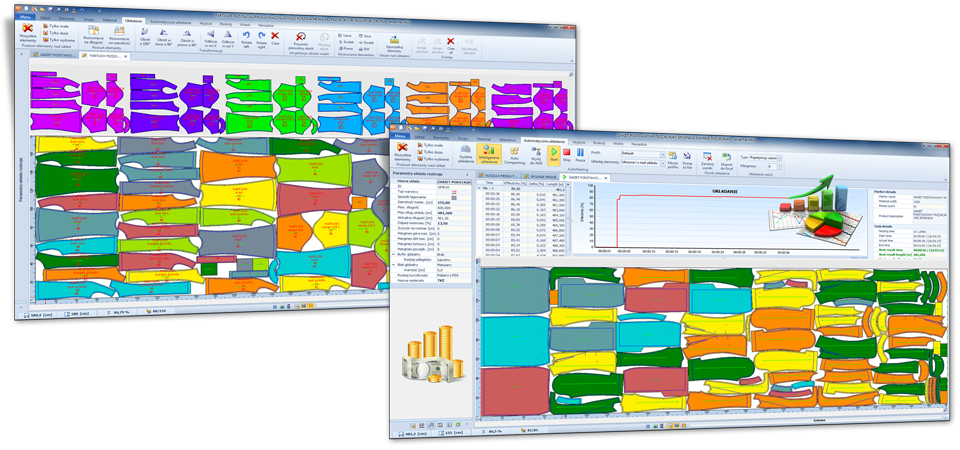

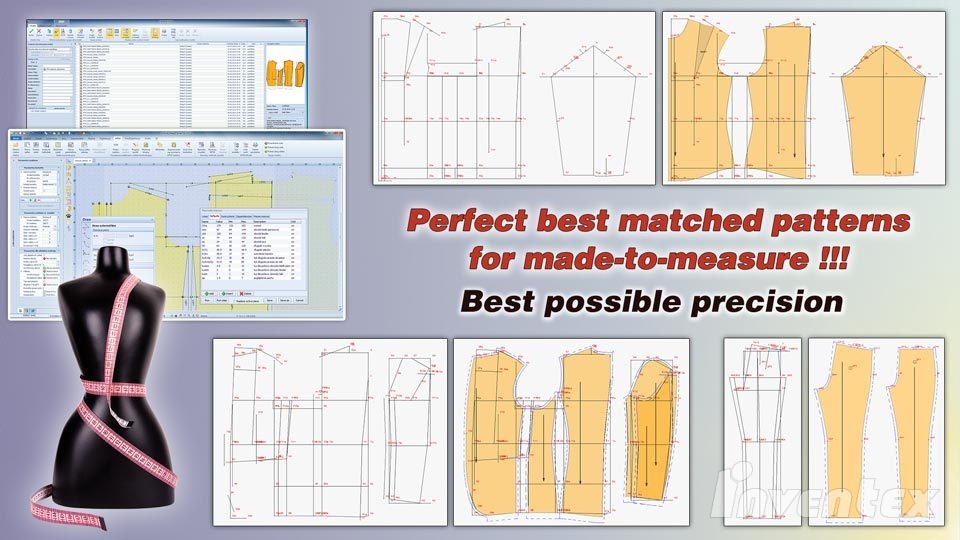

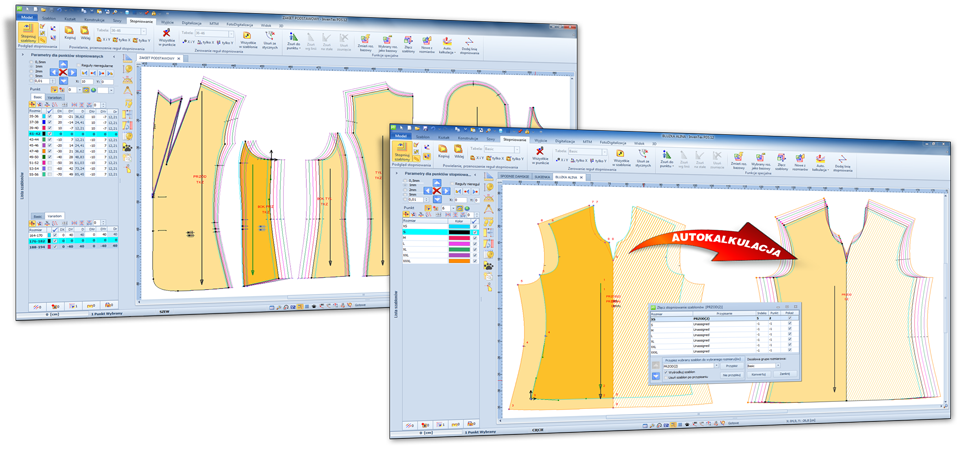

InvenTex PDS is perfectly joining needs of designing and production processes. InvenTex PDS allows creation of highest quality, arbitrary type of men’s, women’s and children’s clothing, underwear, swimsuits, workwear and uniforms – from the simplest to the most advanced projects. The software is perfectly suited for construction and production preparation in the fields of car upholstery, upholstered furniture, accessories and other textile products. InvenTex PDS allows extremely fast creation of new patterns and modification of existing ones thanks to highly effective modern methods of direct work utilizing a computer, eliminating ineffective, error-prone manual work with paper-made patterns. Advanced tools provide fast and easy ways to create and shape lines and outlines, reducing to the minimum the quantity of points which define contour of a pattern. Wide range of easy to use functions allowing to create darts, folds, hems and many other time-consuming and difficult to construct objects, greatly accelerates and increases creativity of the constructor. Additionally, to provide highest possible standards of patterns creating, a perfect set of tools for patterns making utilizing interactive construction grids were created. InvenTex PDS has also a perfect implementation of seams support allowing for dynamic creation of seam allowances, which are automatically adjusting their shapes to changes of forms. InvenTex PDS is equipped with very innovative tools for dynamic measurements, control and verification of shapes and grading of patterns. Interactive measurement table assures best mutual matching of patterns.

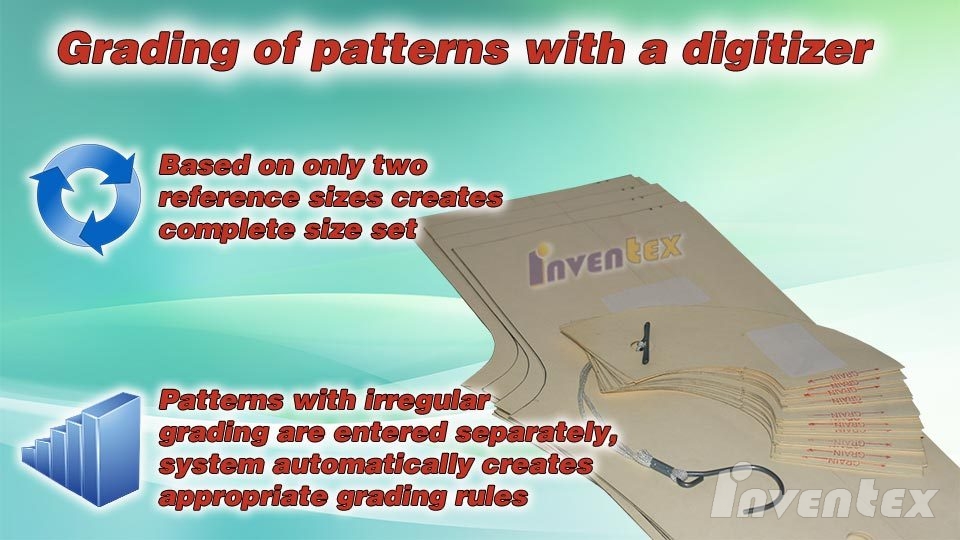

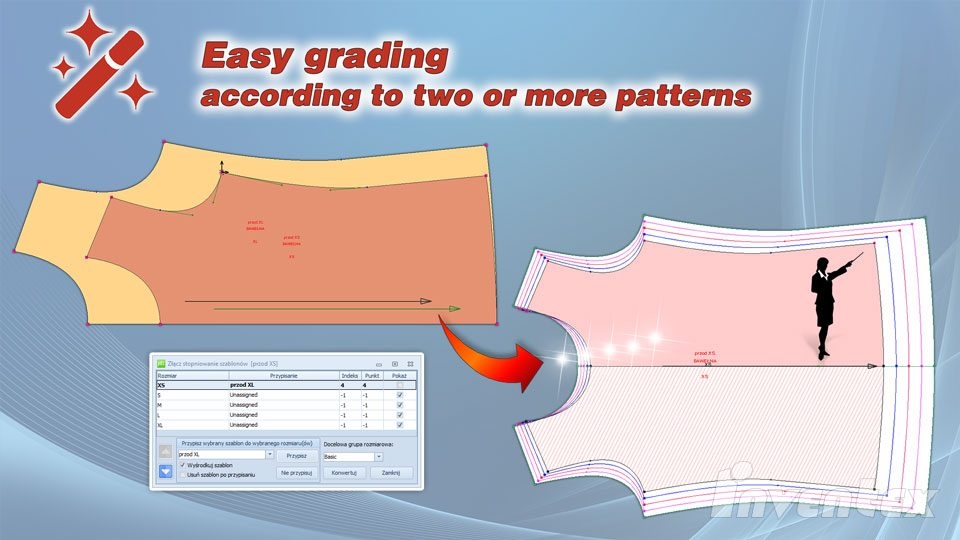

One of the most important modules for manufacturers and an integral part of InvenTex PDS is the PGS module designed for quick and perfect grading of patterns. InvenTex Furniture version is meant for the manufacturers of upholstered furniture and other fields of technical textile and it’s delivered without the PGS module, therefore it can be offered at much better price in comparison to other solutions available from different suppliers.

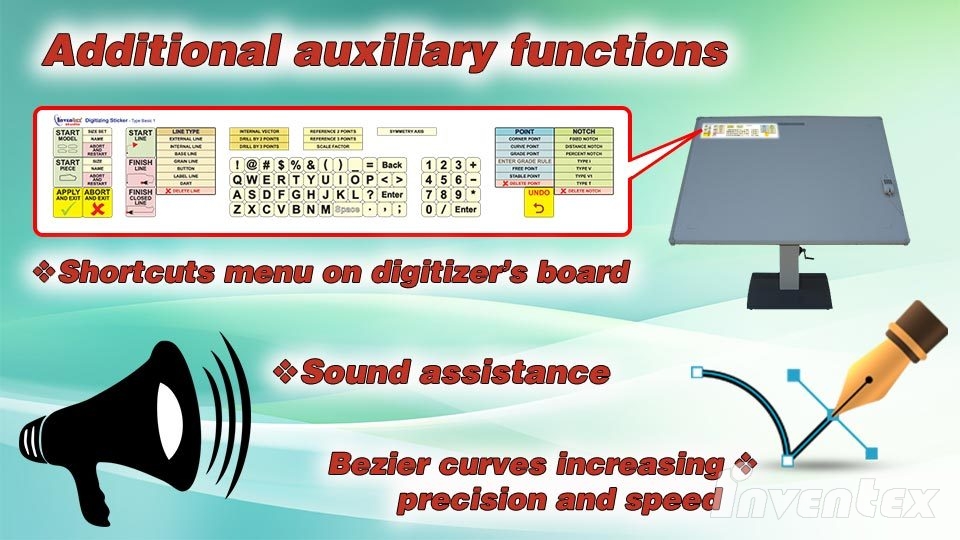

All other additional modules cooperating with InvenTex PDS were also completely integrated to provide best cooperation between modules, ease of use and ergonomy of work. Functions and icons for the additional modules are shown in separate tabs in the main InvenTex PDS menu (ribbon).

Advantages for the user:

- modern and intuitive module which is quickly introduced into production

- significantly reduced time of new models and patterns creation

- easy to use, more accessible for users with smaller experience in construction

- functionality and wide range of construction and modelling tools

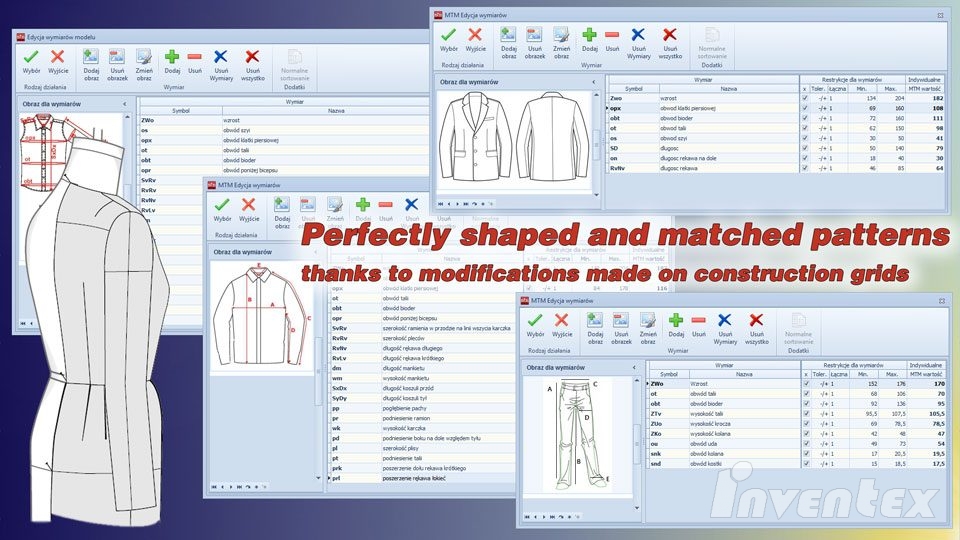

- advanced patterns measuring and control methods

- very good support for seams and notches, sewing technology can be easily modified

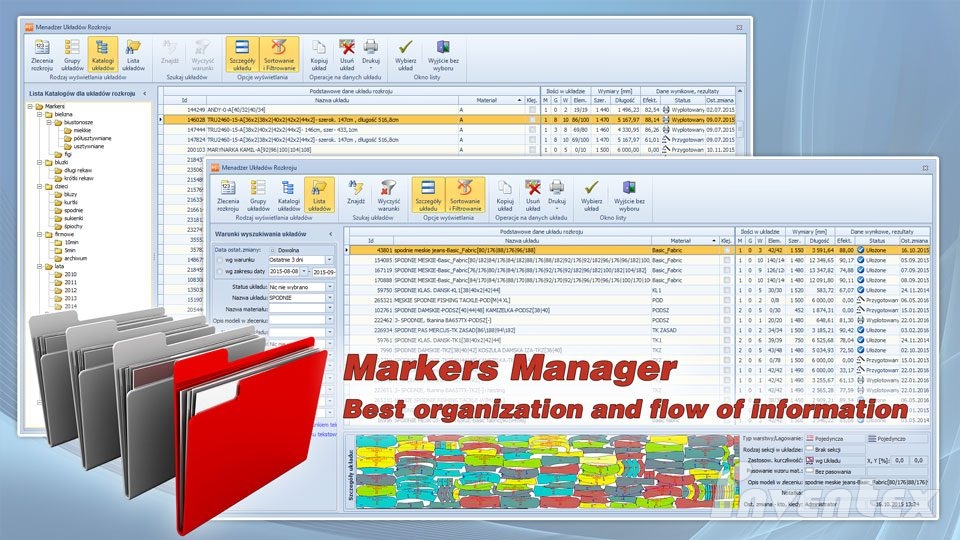

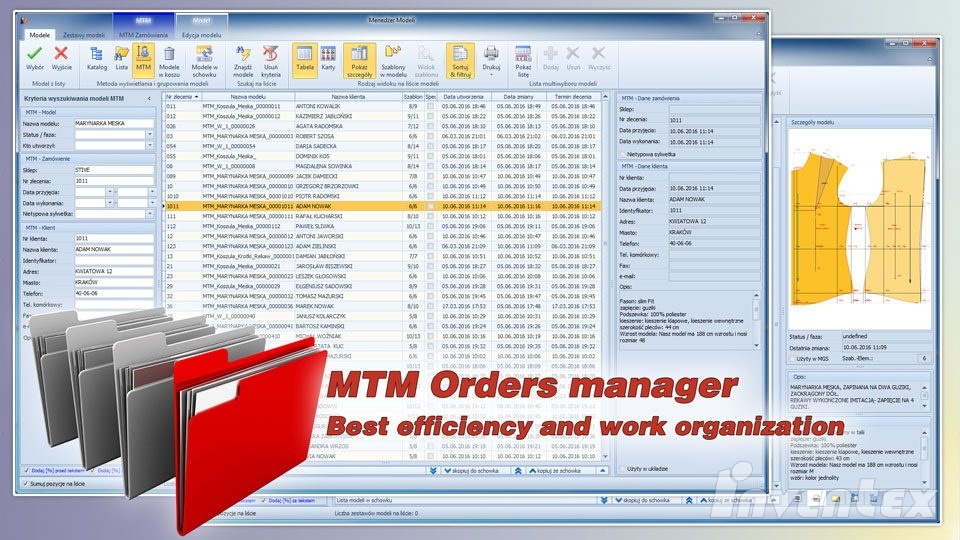

- best of currently available model cataloging and searching function

- embedded miniPDM facilitates cataloging and creation of documentation

- central database with information about models improves company organization

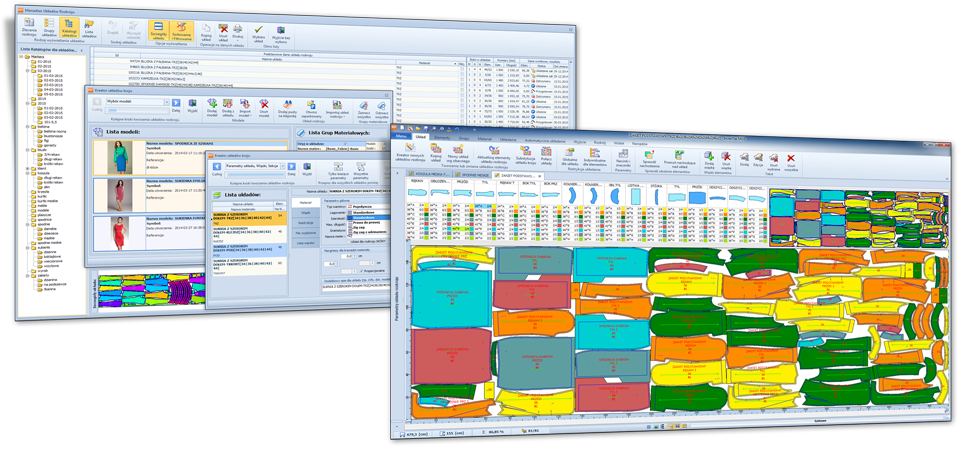

- production versions support increases productivity and eliminates errors

- full history of model changes provides better control on introduced changes

- InvenTex system restore points facilitates creation of multiple variants

- warranty of high speed and creativity in creation of new collections

- reduction of production costs and increase of savings in following years

- assured increase of competitiveness and advantage over competition

Modelling and construction functions

… see the possibilities and the end results!

Fullness

- easy to use function allowing to obtain advanced and interesting patterns constructions in a very short time

- just one click is enough to display window where we can choose the type, size and quantity of inserted bulges… and we’re done!!!

- of course you still can cut the pattern and insert bulges one by one, but why? With modern InvenTex system at hand it’s so easy!

- functions for creative, multiple widening and fitting of patterns are eliminating time-consuming manual cutting and modelling

Inserting or removing bulges

Widening or narrowing of some part of the pattern with a bulge

- widening or narrowing by cutting-out part of the patterns it’s one of most common construction modifications

- InvenTex PDS module provides effective and extremely intuitive tool for this kind of work

- easy interface and interactive preview yet before final approval of the operation provides quick and best end result

- this function is automatically modifying graded patterns in all sizes

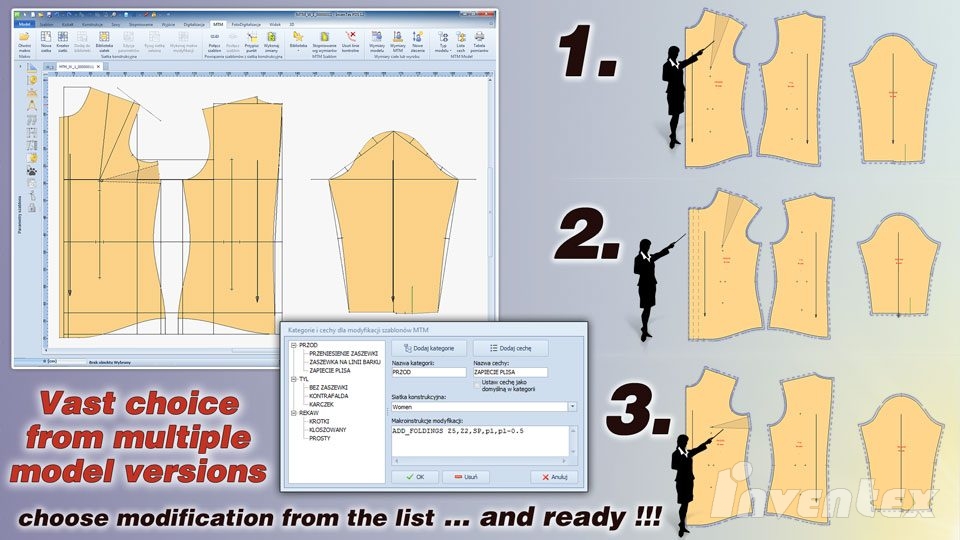

Pleats, folds, box-pleats, pin-tucks

- important and frequently used construction function allowing to obtain advanced end-results in the InvenTex system quickly and easily

- with one dialog window and using one easy to use „multifunction” we can make many attractive modifications

- a few available methods and types of operations with specification of quantity of created pleats of folds

- additionally possibility to create non-standard pleats with variable width and mutual distance

- innovative functionality allowing to control pleats by closing them in order to check and adjust matching of shapes

Inserting of darts

- creation of darts is one of most advanced functions of the system and an indication of its class and functionality

- by means of an easy to use dialog window we can insert the dart in selected position on the pattern, with possibility to modify it in any time by specifying new parameters in its dialog window

- it’s possible to insert narrowing dart, widening dart or internal dart, with specification if it has to be folded or cut-out

- automatic, correct shaping of the dart’s peak

- innovative function of easy to use closing (sewing) of one or multiple darts in order to control and adjust the shape or to perform control measuring with closed dart

Transferring of darts

- easy moving of chosen dart to different position on the pattern with automatic creation of new or additional dart

- possibility to move whole dart with automatic closing or only part of it

- function to distribute the dart over multiple positions on the pattern, each part of different size

- pin point of dart can be easily moved to another place eg to secure unwanted detachment of pattern’s fragment in a position where pin points of a few darts are close to each other

Adding buttons, button holes, points

Fast and precise adding of multiple buttons, button holes, marker points

- fast and precise function for adding of multiple buttons, button holes or other marker points by means of easy to use dialog window

- function allowing to distribute given quantity of buttons over a declared distance or adding with specified offset between buttons, button holes, etc

- first and last button/hole can be added following different rules or can be omitted

- possibility to define line of distribution along which subsequent buttons/holes will be added, eg pattern’s edge, with easy to use margins

- easy selection of marker type and its additional parameters

Interactive patterns matching

- highly comfortable method of interactive pattern matching, simulating traditional measurement of patterns

- patterns can be transposed in reference to themselves, according to specified coefficient simulating traditional gathering during sewing

- available excellent tools for precise measuring and verification of notches with possibility to add a notch in certain place

- work with a group of patterns, easy switching from point to point, quick control of the gathering amount

- patterns with darts and pleats are no problem anymore as these elements can be closed automatically

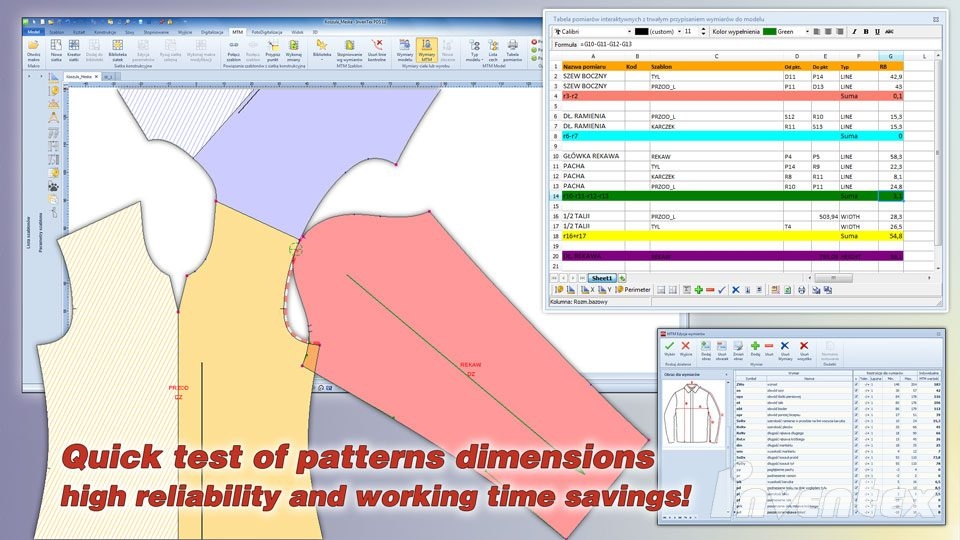

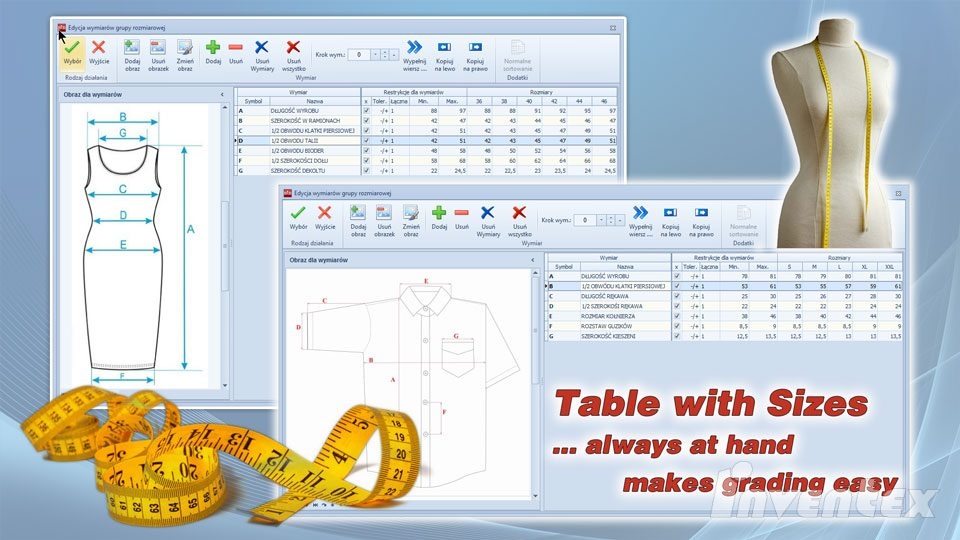

Interactive measurments table

- perfect, easy to use and innovative method of dynamic patterns matching control

- with just a few interactive functions we can create a list of multiple, mutually dependant measurements, which can be saved in spreadsheet table, similar to classic Excel program

- dimensions are automatically re-calculated after each change of pattern’s shape, in all sizes at once

- measurements created in this table are saved together with respective model can be displayed or modified anytime

- easy verification of graded patterns

Base pattern - one click on selected function … lots of possibilities